Semtool Engineering in Melbourne offers cylindrical grinding services to enhance tolerance and surface quality in precision components.

Cylindrical grinding services are essential for achieving high precision and exceptional surface quality in various engineering applications. This process utilises advanced machinery to grind the outer surfaces of cylindrical components, ensuring tight tolerances and smooth finishes. By leveraging these services, businesses can enhance product performance and reduce manufacturing costs, making them a crucial aspect of modern manufacturing.

How Cylindrical Grinding Works

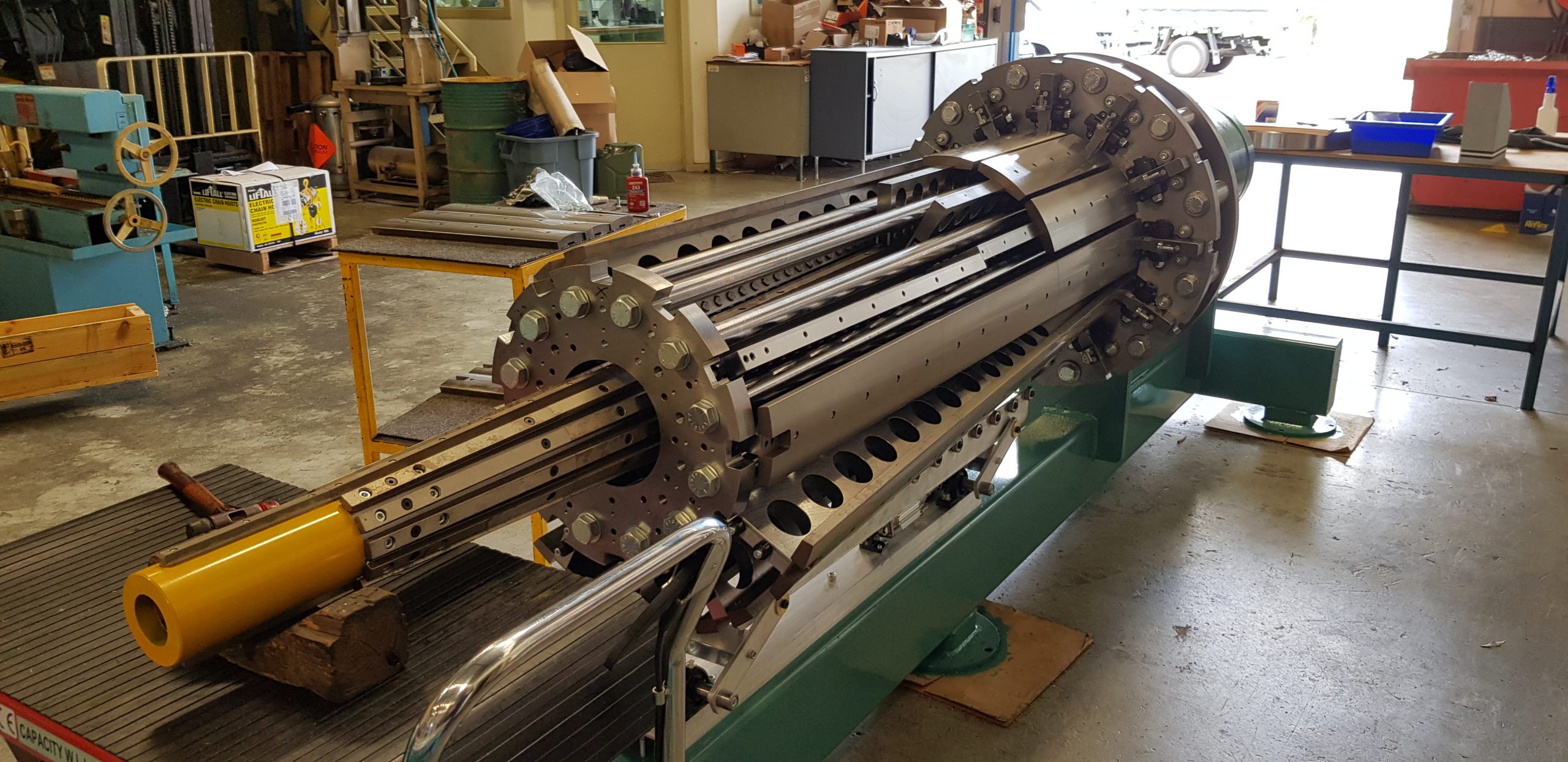

The cylindrical grinding process involves using a rotating grinding wheel to remove material from a workpiece that is also rotating. The grinding wheel is dressed with abrasive particles, which cut away material from the workpiece as it moves across the surface. The process can be performed either wet or dry, depending on the material being ground and the desired surface finish.

The Importance of Tolerance and Surface Quality

In engineering, tolerance refers to the allowable deviation from a specified dimension. High tolerance is essential for ensuring that components fit together correctly and function as intended. Surface quality, on the other hand, relates to the smoothness and finish of the machined surface. Poor surface quality can lead to increased friction, wear, and potential failures in machinery. Thus, achieving high levels of both tolerance and surface quality is critical for the longevity and reliability of components.

Types of Cylindrical Grinding

Understanding the different types of cylindrical grinding is essential for selecting the right method for specific applications. Here are some common types of cylindrical grinding:

• Centerless Grinding: In this method, the workpiece is supported by a work rest blade and a regulating wheel that controls its rotation and position. It is particularly effective for grinding long, slender workpieces with high efficiency.

• Through-Feed Grinding: This technique involves feeding the workpiece through the grinding wheel in a single pass. It is ideal for workpieces with a relatively uniform cross-section, allowing for quick and consistent grinding.

• In-Feed Grinding: In this approach, the workpiece is fed into the grinding wheel in multiple passes. This method provides greater control over the surface finish and is often used for grinding complex shapes or components requiring a very high surface quality.

Choosing the Right Cylindrical Grinding Service

Choosing the right cylindrical grinding service is crucial to achieving optimal results in your manufacturing processes. Here are some key considerations when choosing a cylindrical grinding service:

• Machining Capabilities: The service provider should possess the necessary equipment and expertise to perform the specific type of grinding required. This ensures that they can handle your project effectively and efficiently.

• Quality Control: A robust quality control system is essential for ensuring that finished components meet the specified tolerances and surface finish requirements. This guarantees reliability and consistency in the products you receive.

• Experience: Look for a service provider with experience in grinding similar types of components. Their familiarity with specific materials and processes will contribute to higher-quality results.

• Delivery Times: Ensure that the service provider can meet your required delivery deadlines. Timely delivery is crucial for maintaining your production schedule and avoiding delays.

Cylindrical grinding is a critical process for achieving high-quality, precision-engineered components. By choosing Semtool Engineering for your cylindrical grinding needs, you can benefit from our expertise, state-of-the-art equipment, and commitment to delivering exceptional results.