Elevate tactical operations with Australian defence manufacturing from Semtool Engineering, delivering quality machinery and spare parts in Melbourne.

Australian defence manufacturing enables advanced tactical equipment and military hardware to maintain reliability and operational efficiency in complex environments. The discipline addresses industry requirements for resilience, ensuring mission-critical equipment meets the rigorous demands of military applications through a combination of controlled processes and stringent standards.

Advancing Tactical Equipment Reliability

Manufacturing tailored for defence applications ensures operational reliability and consistency across tactical equipment used in challenging environments. Each component undergoes thorough inspection and rigorous quality checks, ensuring the finished products can withstand high pressure and unpredictable situations.

Local production leverages specialist process controls and industry-specific standards, facilitating dependable performance throughout operational cycles. Strict adherence to quality benchmarks and robust testing protocols safeguards the integrity of every product, making certain that tactical systems perform at optimum levels during field deployment.

Precision Components in Australian Defence Manufacturing

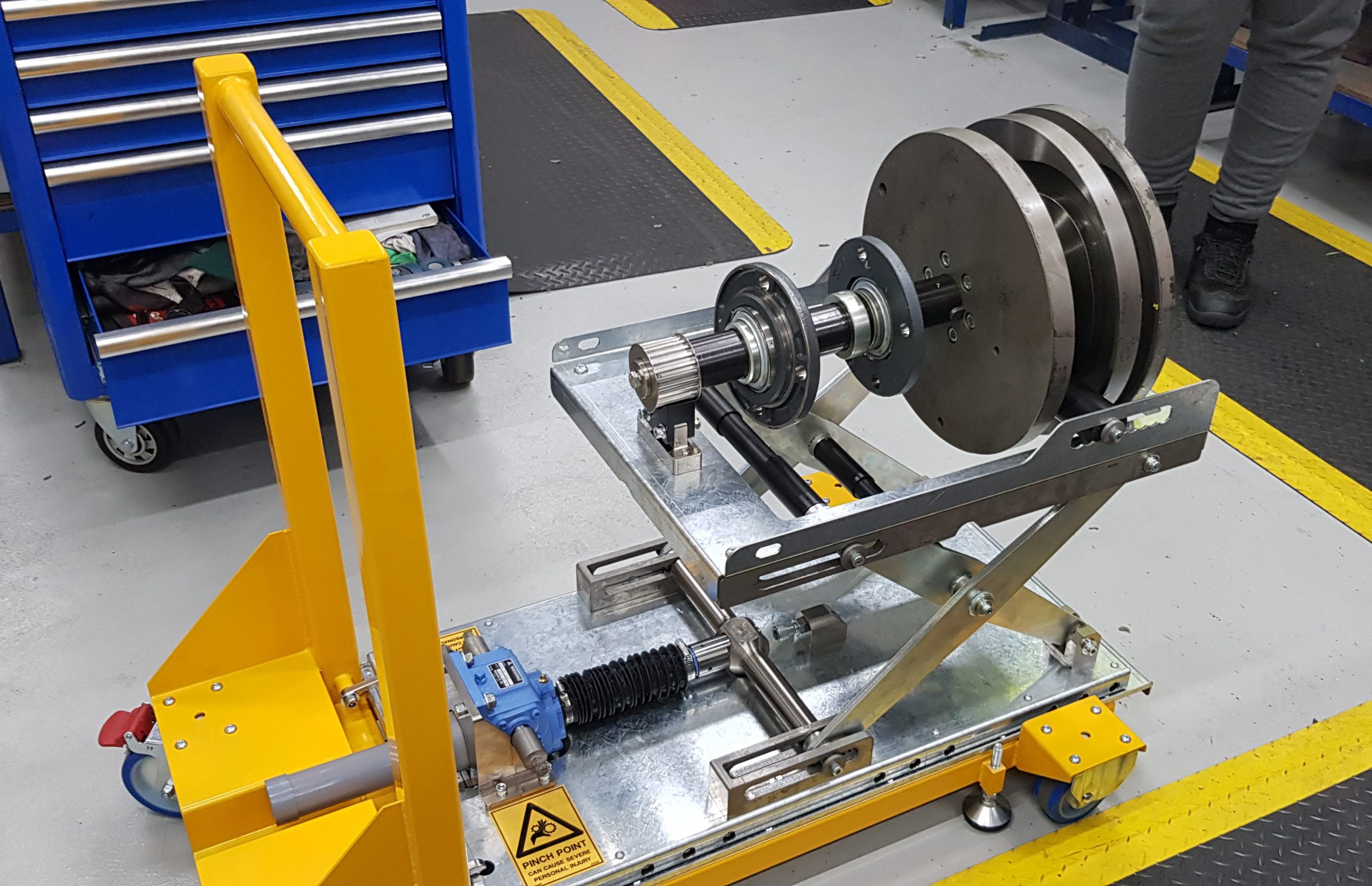

Production of precision components for defence manufacturing integrates advanced technologies, allowing for micron-level tolerances necessary for contemporary military equipment. Equipment such as CNC machines, automated inspection systems, and state-of-the-art metrology tools delivers repeatable accuracy, underpinning the operational reliability of sophisticated weaponry and support systems.

Key aspects highlighted in precision manufacturing:

• Micron-level Tolerances: Precise measurements contribute to component consistency and seamless system integration.

• Multi-axis CNC Machining: Advanced equipment supports complex geometries required for modern defence hardware.

• Non-destructive Testing: Inspection methods guarantee component quality without compromising structural integrity.

• Automated Assembly Lines: Enhanced throughput and uniformity in production outputs.

• Quality Control Audits: Regular process assessments sustain continuous improvement across manufacturing stages.

Innovations Driving Australian Defence Manufacturing

Ongoing technological advancements support new possibilities in Australian defence manufacturing, raising the standard for tactical equipment and military hardware. Industry research fosters material development and process automation, resulting in more resilient and capable solutions.

Recent innovations driving progress:

• Advanced Robotics: Automated handling and precision placement increase efficiency and safety.

• Smart Materials: Lightweight composites improve durability and adaptability.

• Digital Twin Technology: Virtual simulations streamline prototyping and reduce production risks.

• Predictive Maintenance Tools: Early identification of component wear enhances equipment longevity.

• Additive Manufacturing: 3D printing expands design flexibility and rapid prototyping capabilities.

• Integrated Data Systems: Real-time process monitoring improves traceability and reporting.

• Laser-based Metrology: High-precision inspection methods ensure dimensional accuracy in complex assemblies.

Each development in process automation, inspection, and material science refines the output quality, delivering tactical solutions ready for deployment in contemporary defence settings.

The Future of Australian Defence Manufacturing

Every solution from Semtool Engineering reflects a dedication to quality, innovation, and practical outcomes across the defence sector. We approach each challenge with a focus on delivering machinery, spare parts, and engineering services that meet the unique demands of our clients, ensuring reliability from concept to completion.

Contact us at Semtool Engineering for tailored engineering components.