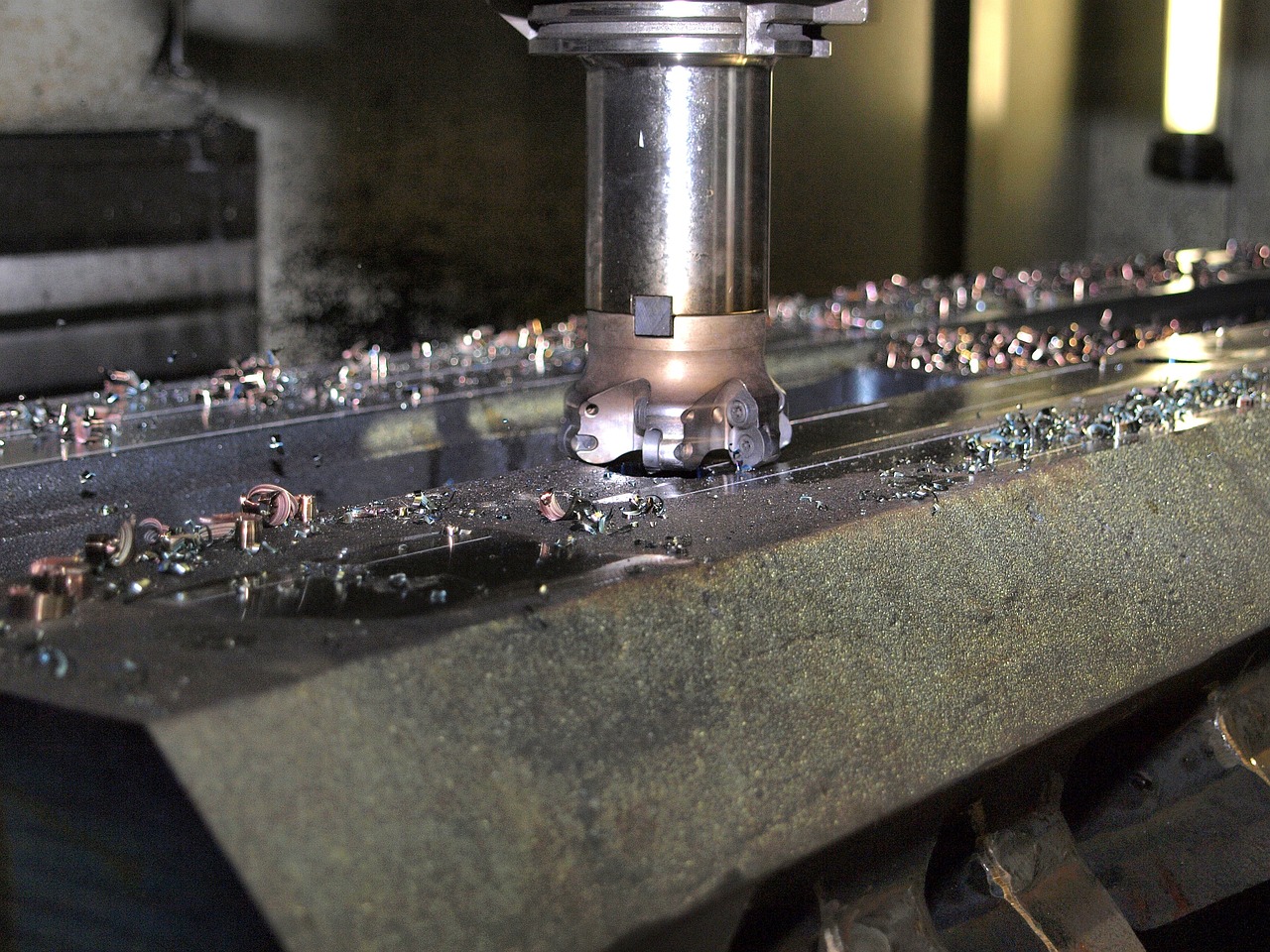

Semtool Engineering provides expert machining titanium grade 5 services in Melbourne, focused on precision and efficiency.

Titanium Grade 5, or Ti-6Al-4V, is a premium alloy valued for its exceptional strength, corrosion resistance and low density. Despite these advantages, machining titanium grade 5 requires expert control due to its low thermal conductivity and high reactivity at elevated temperatures. These properties cause excessive heat retention and accelerated tool wear, making process optimisation essential for achieving high dimensional accuracy and consistent surface finishes.

Effective Heat Control in Titanium Machining

Machining titanium grade 5 concentrates heat at the cutting edge rather than dispersing it through chips. The retained heat accelerates tool wear, reduces dimensional accuracy and may cause workpiece distortion. Temperature control remains essential for achieving precision and extending tool life.

Balanced cutting speed and feed rate reduce heat generation and friction at the tool–workpiece interface. High-pressure coolant systems improve chip evacuation and keep cutting temperatures consistent. Continuous chip removal further stabilises the process, improving surface quality and ensuring longer tool performance.

Tooling Considerations for Titanium Alloys

Selecting the appropriate cutting tool is vital to sustain accuracy and productivity during machining titanium grade 5. The combination of high heat and chemical reactivity demands specialised materials and coatings that resist adhesion and deformation.

Recommended tooling practices include:

• Carbide Cutting Tools: These tools offer excellent hardness and wear resistance, allowing precise performance under the high temperatures generated when machining titanium grade 5.

• PVD-Coated Inserts: Titanium aluminium nitride coatings reduce friction and adhesion, extending tool life and improving cutting consistency in titanium machining.

• Positive Rake Geometry: Sharp edges with positive rake angles minimise cutting forces, enhance chip flow, and reduce thermal stress on the tool.

• Rigid Tool Holders: Stable and well-balanced tool clamping systems prevent vibration, maintaining dimensional accuracy and superior surface finishes.

• Wear Monitoring Systems: Real-time detection of flank wear enables proactive tool replacement, ensuring consistent quality and reduced downtime.

The right tool geometry and coating selection can substantially improve process stability, surface quality and cutting efficiency.

Optimised Machining Techniques for Surface Quality

Advanced machining strategies enable smoother cutting actions and controlled thermal conditions when working with titanium. Precision CNC systems combined with adaptive tool paths can enhance both efficiency and surface finish.

Key methods include:

• Maintaining consistent radial engagement to prevent thermal shock.

• Using climb milling to achieve cleaner chip formation and minimise deflection.

• Allowing short cooling intervals between tool passes to stabilise heat distribution.

• Adjusting feed rates to maintain steady cutting forces and improve efficiency.

• Employing stable CNC tool paths to ensure uniform material removal and accuracy.

These techniques provide higher repeatability, reduce vibration and contribute to uniform component quality in production environments.

Expert Titanium Machining by Semtool Engineering

Achieving precision in machining titanium grade 5 requires a deep understanding of metallurgy, tool dynamics and process optimisation. At Semtool Engineering, we deliver high-performance CNC machining solutions that ensure consistent quality across critical titanium applications.

Our advanced capabilities, industry expertise and commitment to accuracy make us a trusted partner for clients in aerospace, medical and heavy industrial sectors.

Contact us at Semtool Engineering to learn your titanium machining requirements and discover how our precision services can enhance your production performance.

Related Blog Article: Conventional Milling “Hard-to-Machine” Materials: Challenges and Solutions