Reduce downtime and operating costs using custom machine design solutions from Semtool Engineering in Melbourne for heavy-duty manufacturing automation.

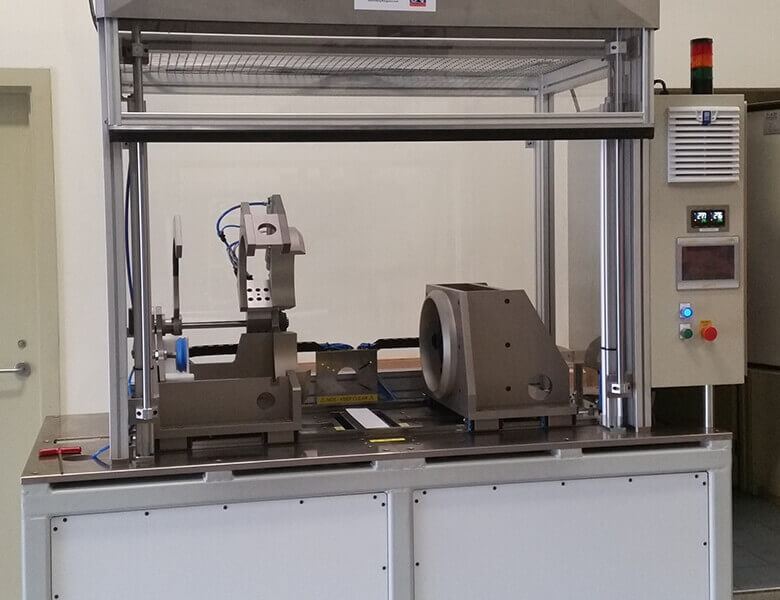

Heavy-duty manufacturing requires machinery that delivers precision, durability, and predictable operating costs. Custom machine design supports advanced automation by aligning equipment performance with demanding production conditions and long-term cost objectives. Purpose-built systems allow manufacturers to improve throughput while maintaining operational control.

Engineering Automation for Industrial Performance

Manufacturing environments operating under high loads and continuous cycles place significant stress on standardised equipment. Automation systems developed specifically for the application improve reliability by matching mechanical strength, control accuracy, and material selection to real production demands.

Custom machine design enables automation solutions to address inefficiencies related to speed variation, component wear, and inconsistent output. Machines engineered for heavy-duty use maintain stable performance across extended operating hours, supporting repeatable production without excessive maintenance intervention.

Integrating Custom Machine Design into Manufacturing Systems

Automation delivers the strongest return when equipment integrates seamlessly into existing production lines. Custom machine design allows engineers to account for spatial limitations, material flow requirements, and interface compatibility with current systems.

Machine layouts, guarding, and control platforms are configured to meet Australian safety standards while supporting efficient operator interaction. Purpose-designed automation reduces downtime during commissioning and simplifies future system expansion without disrupting ongoing operations.

Operational Advantages of Tailored Automation Systems

Automation systems engineered for specific manufacturing conditions deliver measurable operational benefits across production and maintenance activities.

• Process Accuracy: Precisely controlled motion systems maintain tight tolerances across continuous, high-cycle production environments.

• Cycle Time Reduction: Optimised automated sequencing increases throughput while preserving mechanical integrity and system reliability.

• Labour Efficiency: Automation reduces manual intervention, improving operator safety, lowering fatigue, and minimising process variability.

• Equipment Longevity: Load-rated mechanical and electrical components are engineered to perform reliably under sustained heavy-duty conditions.

• Production Consistency: Repeatable automated processes ensure stable output quality across multiple shifts and operating cycles.

Cost Control Through Purpose-Built Machine Engineering

Long-term cost control depends on automation systems designed for efficiency across the full equipment lifecycle. Purpose-built machine solutions allow informed selection of drives, materials, and control hardware to balance capital investment with operational savings.

• Energy Optimisation: Appropriately sized motors and drive systems minimise energy consumption under varying operational loads.

• Maintenance Accessibility: Purpose-designed access points simplify inspections, servicing, and component replacement, reducing downtime.

• Reduced Scrap Rates: High-precision automation maintains dimensional control, lowering material waste and rework requirements.

• Scalable Architecture: Modular system design enables future capacity expansion or process changes without full equipment replacement.

• Compliance Alignment: Machinery and control systems are engineered to comply with Australian safety, electrical, and operational standards.

Review the Work Australia – Managing Risks of Plant in the Workplace Code of Practice for compliant machinery design and risk management principles:

Engineered Automation Solutions for Industrial Growth

Heavy-duty manufacturers achieve sustainable efficiency gains through automation systems engineered for their exact operating conditions.

Semtool Engineering delivers engineered automation and machine solutions that enhance performance, safety, and long-term cost control for Australian manufacturers. Through custom machine design, our production systems are developed to meet demanding operational requirements while supporting reliable, efficient automation.

Contact us to assess automation opportunities within your existing production systems.

Related Blog Article: Custom Machine Design & Manufacturing for Production Efficiency