Explore advancements in cylindrical grinding for enhanced surface finish and accuracy. Let Semtool Engineering revolutionise precision machining today!

In precision machining, superior surface finish and accuracy can be achieved through cylindrical grinding. Cylindrical grinding, a key process in precision machining, helps components for the aerospace, automotive, medical, or manufacturing industries to meet stringent quality standards, ensure optimal performance, and maintain reliability.

The Process of Cylindrical Grinding

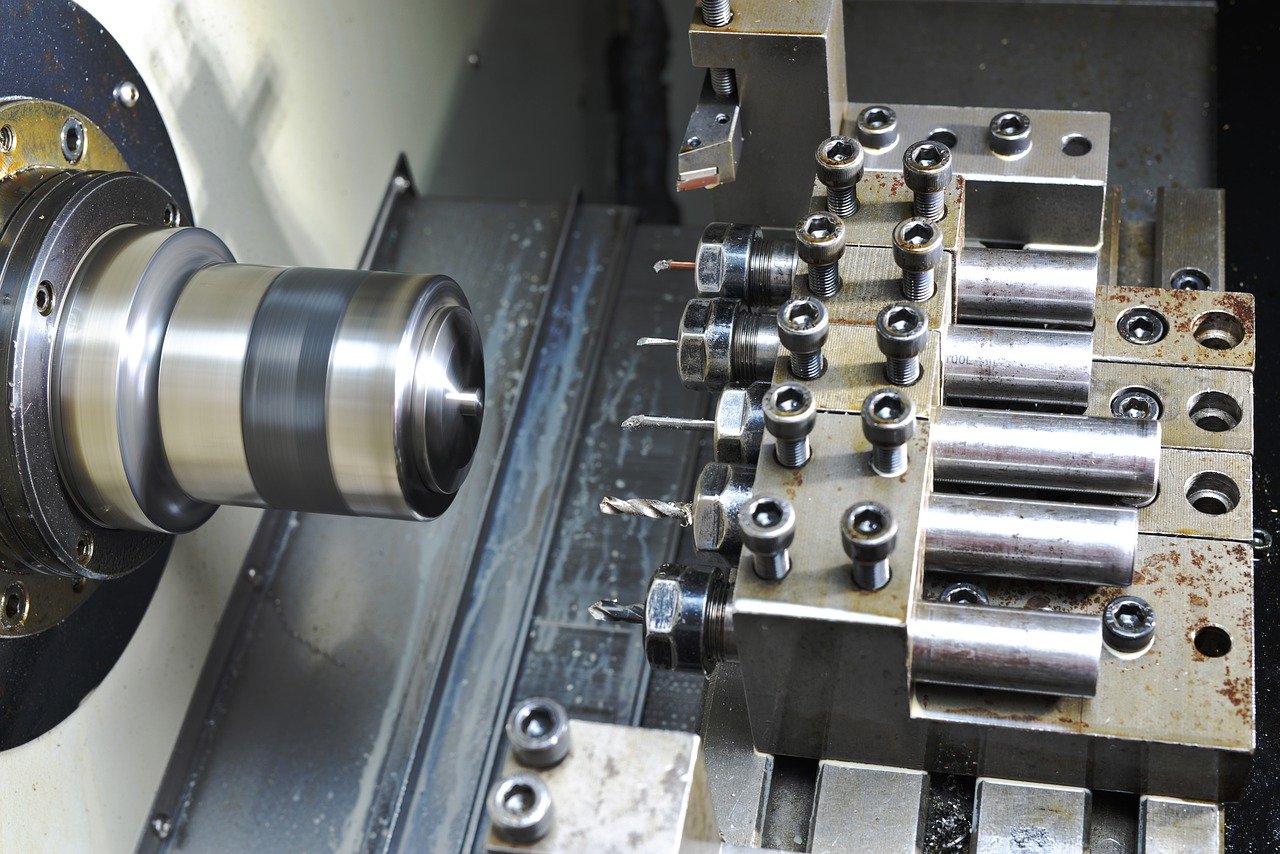

Cylindrical grinding is a machining process used to produce precise cylindrical shapes and achieve tight tolerances on cylindrical surfaces. It involves the use of a cylindrical grinder, typically equipped with abrasive wheels, to remove material from the workpiece and create the desired geometry. This process is widely employed in the production of shafts, bearings, pistons, gears, and other cylindrical components requiring high precision and surface quality.

Innovations in Grinding Technology

Recent advancements in grinding technology have led to significant improvements in surface finish, accuracy, and efficiency. Some notable advancements that Semtool Engineering use or implement in cylindrical grinding are as follows.

• High-Performance Grinding Wheels: Modern abrasive materials and bonding systems have revolutionised grinding wheel technology, allowing for higher material removal rates, improved surface finish, and longer wheel life. We maximise wheels with advanced abrasive grains as they offer superior cutting performance and thermal stability.

• Precision Grinding Machines: State-of-the-art CNC or Computer Numerical Control grinding machines incorporate advanced features such as adaptive control, in-process gauging, and automatic wheel dressing. We use them as they allow for precise control over grinding parameters, ensuring consistent quality and dimensional accuracy across multiple workpieces.

• Multi-Process Machining: Integrated grinding systems that combine cylindrical grinding with other machining processes, such as turning and milling, offer enhanced versatility and productivity. We maximise multi-process machining centres to streamline production workflows, reduce setup times, and eliminate the need for multiple machine setups.

Key Benefits of Cylindrical Grinding

The adoption of advanced cylindrical grinding technology offers several key benefits for precision machining applications.

First, advanced grinding techniques and high-performance grinding wheels can help produce smoother surface finishes with reduced waviness, roughness, and defects. Precision grinding machines equipped with advanced control systems and in-process gauging mechanisms can likewise ensure dimensional accuracy and consistency, even in high-volume production environments. Tighter tolerances enable seamless assembly, better part interchangeability, and improved product quality.

Faster material removal rates, reduced setup times, and increased automation capabilities also contribute to higher productivity and throughput. Advanced grinding technology enables us to meet demanding production schedules while maintaining quality standards and cost competitiveness.

All these benefits of advanced cylindrical grinding technology are deemed useful to many industries in processing different components. Some of these components are turbine blades, engine shafts, landing gear, engine components, transmission parts, steering systems, surgical implants, orthopaedic instruments, and dental prosthetics.

Working with Semtool Engineering

Advancements in cylindrical grinding technology have transformed precision machining, enabling Semtool Engineering to achieve superior surface finish, dimensional accuracy, and productivity. With the adoption of high-performance grinding wheels, precision grinding machines, and multi-process machining systems, we can meet the exacting demands of today’s industries while maintaining a competitive edge in the global marketplace.