Automated jig and fixture designs can minimise labour and maximise output in manufacturing. Learn key considerations for implementing these advanced systems.

Automated jig and fixture designs are transforming modern manufacturing by significantly reducing the need for manual labour while boosting productivity. These advanced systems enhance precision and consistency, producing higher-quality outputs with fewer errors. By minimising human intervention, they streamline production processes and enable manufacturers to meet tight deadlines more efficiently.

The Role of Jigs and Fixtures in Manufacturing

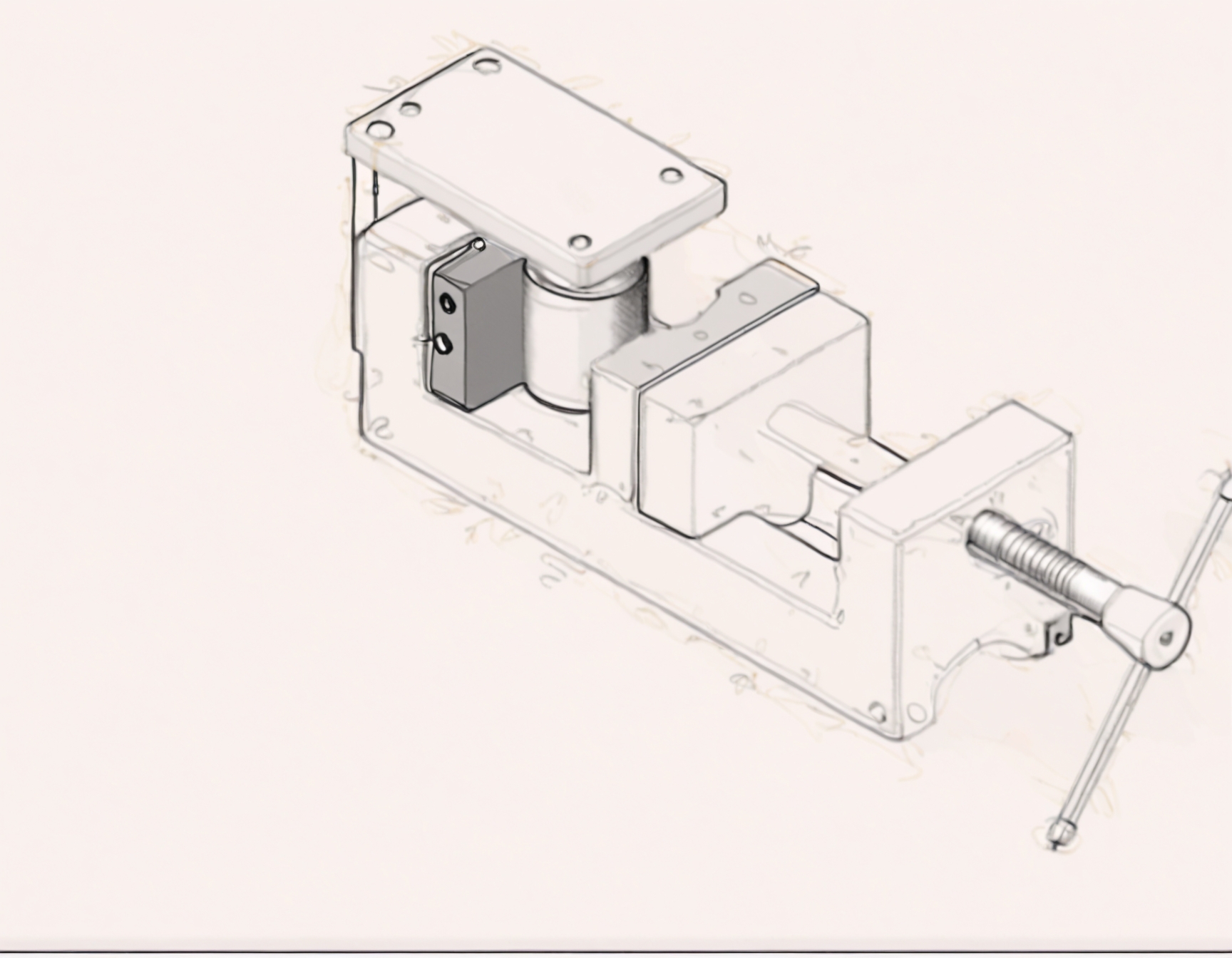

Jigs and fixtures have long been integral to manufacturing processes. They ensure precision, repeatability, and efficiency by securely holding workpieces in place, allowing for accurate machining, welding, or assembly. Traditionally, these tools required manual adjustment and setup, which could be time-consuming and prone to errors.

However, with the advent of automation, jig and fixture designs have evolved significantly. Automated systems now provide enhanced control, adaptability, and precision, leading to a significant reduction in manual labour and an increase in production output.

Applications Across Industries

Automated jig and fixture designs are being utilised across various industries to enhance manufacturing processes significantly. For instance, in the automotive sector, these systems are crucial in accurately positioning components during assembly, ensuring that each vehicle meets strict quality standards. The precision provided by automated jigs and fixtures helps to eliminate errors and maintain consistency, which is vital in an industry where safety and performance are non-negotiable.

Similarly, in the aerospace industry, automated jigs and fixtures play a vital role in the precise machining of aircraft components. Accuracy is paramount in aerospace manufacturing, where even the smallest deviation can lead to significant issues. Automated systems ensure that every part is produced to exact specifications, reducing the risk of defects and enhancing the overall safety and reliability of aircraft.

Implementing Automated Jig and Fixture Designs

For manufacturers looking to implement automated jig and fixture designs, there are several key considerations to keep in mind:

• Product Complexity: The complexity of the product being manufactured will influence the design of the automated system. More complex products may require more sophisticated automation solutions.

• Production Volume: The anticipated production volume will determine the level of investment required in automation technology. Higher production volumes justify greater automation.

• Customisation: Automated jigs and fixtures can be tailored to meet the specific needs of a production line, whether it’s for machining, welding, or assembly. Customisation ensures that the system is optimised for the particular components being produced.

• Integration with Existing Systems: It’s essential to ensure that automated jigs and fixtures can be seamlessly integrated with existing manufacturing equipment and processes. This may require collaboration with equipment suppliers and system integrators.

• Invest in Quality Automation: Choose high-quality automation equipment that is reliable and durable. Investing in the right technology will pay off in the long run through increased productivity and reduced downtime.

• Training and Support: While automation reduces the need for manual labour, it also requires a workforce skilled in operating and maintaining these advanced systems. Providing adequate training and ongoing support is critical to the success of the implementation.

Semtool Engineering is committed to providing innovative and effective automated solutions for our clients. Our team specialises in designing and manufacturing custom jigs and fixtures tailored to specific manufacturing requirements.