Discover the essential aerospace components shaped by CNC machining in our basic guide. Learn how precision engineering drives innovation in aerospace manufacturing.

To ensure the safety and performance of aircraft and spacecraft every component in aerospace engineering must meet its standards. This is where Computer Numerical Control (CNC) machining comes into play, revolutionising the production of aerospace components with unparalleled accuracy and consistency.

The Crucial Role of Aerospace Components

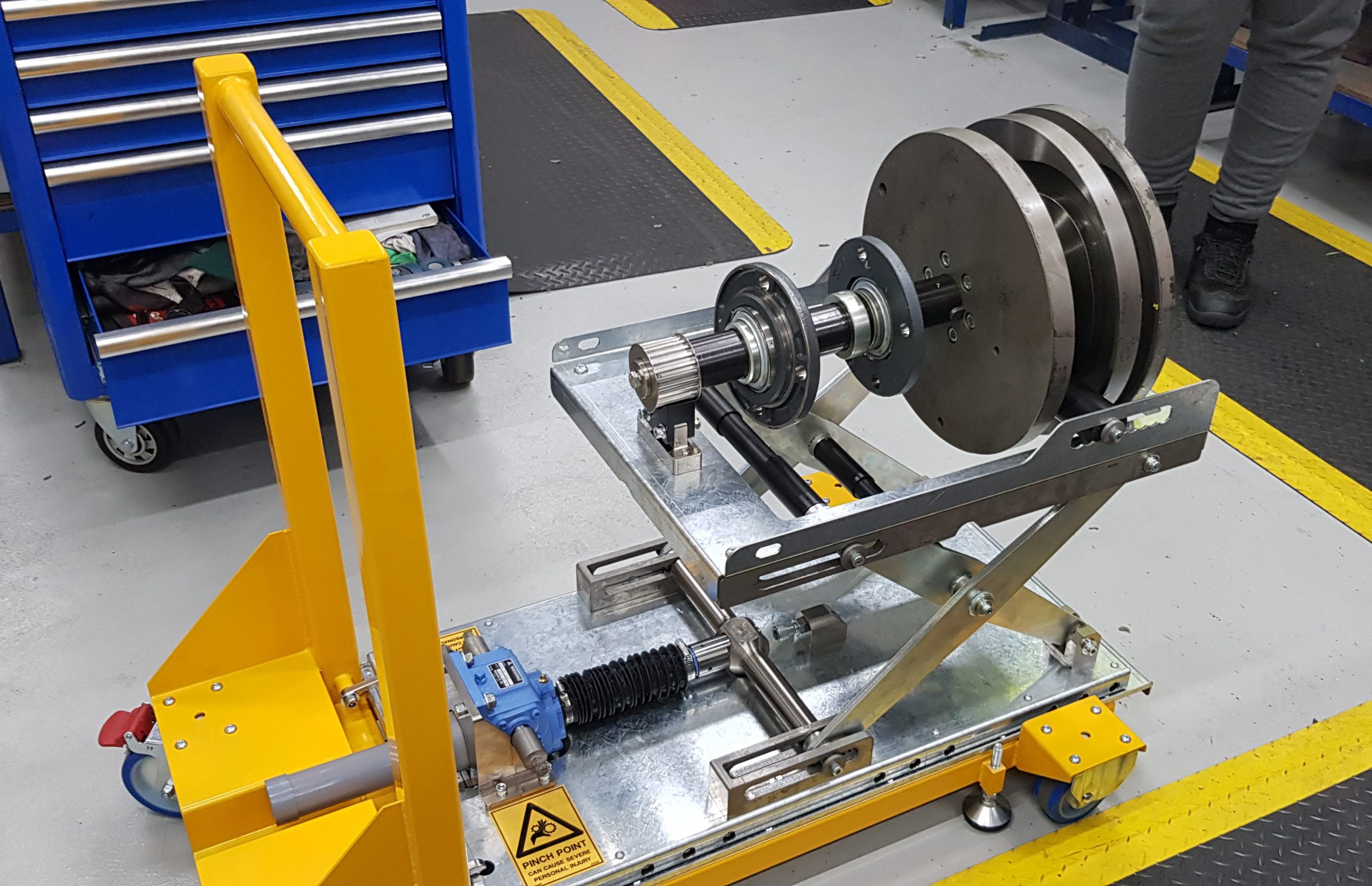

Aerospace components are the building blocks of modern aviation and space exploration. From the structural elements that form the skeleton of an aircraft to the intricate parts that power jet engines, each component plays a vital role in the overall functioning of aerospace vehicles. At Semtool Engineering, we understand the critical nature of these parts and employ state-of-the-art CNC machining to meet the industry’s demanding requirements.

Key Aerospace Components Shaped by CNC Machining

The aerospace industry relies extensively on precision-engineered components produced through CNC machining. These components span a wide range of critical parts for aircraft and spacecraft.

• Structure: Wing ribs and spars, fuselage frames and stringers, and bulkheads are all crucial for aircraft strength and shape.

• Engine: Turbine blades and vanes, compressor discs, and combustion chamber liners are precision-crafted to withstand extreme conditions.

• Landing Gear Parts: Strut assemblies, shock absorber housings, and wheel hubs ensure smooth landings and ground operations.

• Control Surface: Aileron and flap hinges, rudder fittings, and elevator components enable precise aircraft manoeuvrability.

• Hydraulic and Fuel System Parts: Valve bodies, pump housings, manifolds, and fuel injector nozzles are crafted for efficient fluid control and fuel delivery.

• Avionics Housings: Protective enclosures for electronic systems and instrument panels, precisely made to safeguard sensitive equipment.

• Specialised Fasteners and Fittings: High-strength bolts and nuts, custom brackets and clips are essential for secure component joining while minimising weight.

The aerospace industry’s reliance on CNC machining is driven by its ability to produce complex geometries, maintain tight tolerances, and work with specialized aerospace-grade materials like aluminium alloys, titanium, and superalloys. This ensures the high precision, consistency, and efficiency required for safe and reliable aircraft and spacecraft.

The Precision Engineering Process

Creating aerospace components through CNC machining involves a meticulous process that begins with advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software. These tools allow our engineers at Semtool Engineering to design complex parts with incredible detail and program our CNC machines to execute the design with precision.

Most aerospace components require 5-axis CNC machining, which allows for the creation of intricate shapes and contours that would be impossible with traditional manufacturing methods. This advanced technique enables the production of parts with optimal strength-to-weight ratios, a critical factor in aerospace engineering.

Semtool Engineering: Your Partner for Aerospace Components

As a leading CNC machining and precision engineering services company, Semtool Engineering is proud to contribute to the cutting-edge technologies that drive aerospace innovation. From the smallest fasteners to complex engine parts, every component we produce at Semtool Engineering is a testament to our commitment to precision, quality, and innovation in aerospace manufacturing.