Semtool Engineering offers CNC machining services in Melbourne, enabling automotive projects to meet compliance through high-precision solutions.

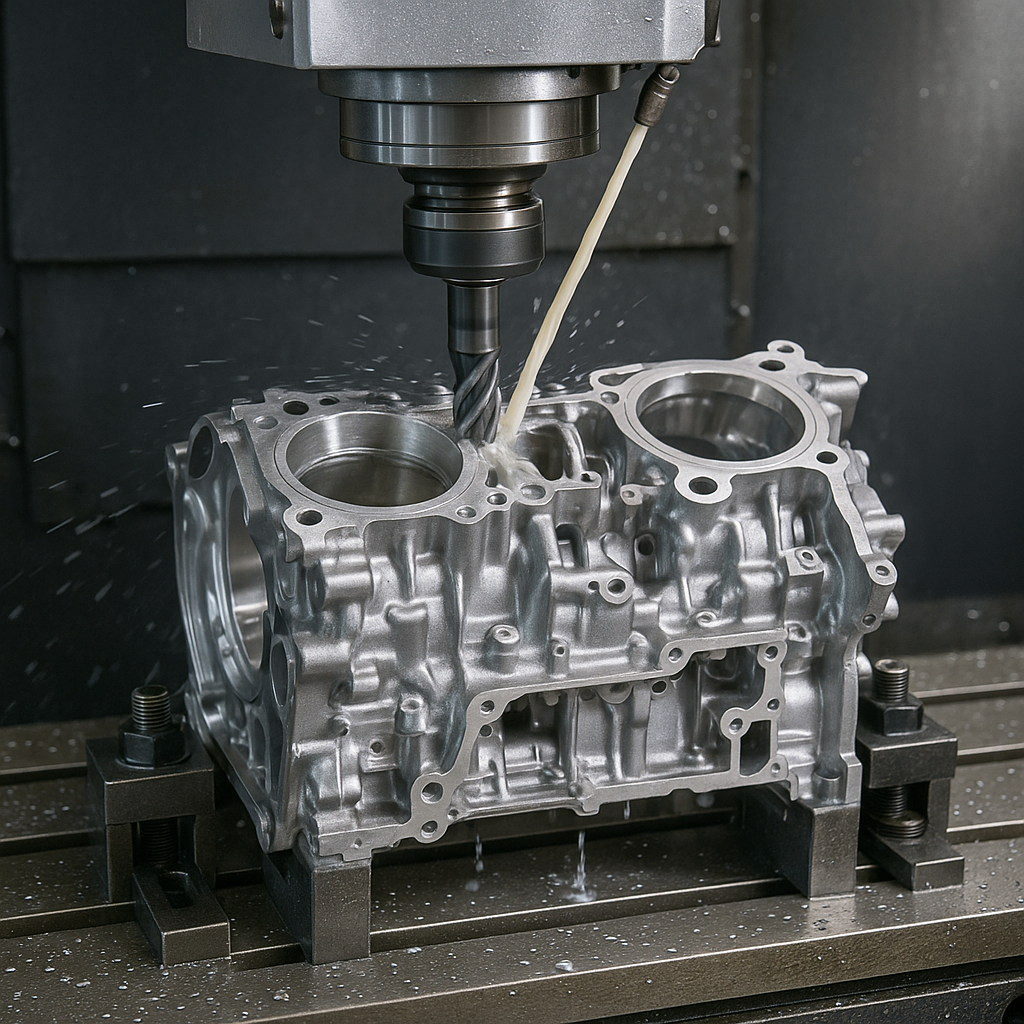

CNC machining services enable accurate fabrication of automotive components that meet strict industry regulations and safety benchmarks. CNC-driven operations provide dependable manufacturing processes that align with modern compliance requirements and are central to supporting production demands in Melbourne’s dynamic automotive sector.

Securing Precision in Automotive Builds Through CNC Machining Services

CNC machining services deliver exceptional dimensional accuracy, ensuring every part adheres to stringent automotive design specifications. Tight tolerances are maintained across production runs, eliminating variation that could compromise assembly integrity or mechanical safety.

Consistency of form and fit across all components enhances operational efficiency and contributes to meeting regulatory guidelines. Automotive builds require systems that prioritise safety, and the precise execution of each component directly supports this standard.

Mechanical alignment, heat resistance, and load-bearing requirements are met through tailored CNC processes designed for automotive builds. Every detail in the production is calculated to strengthen vehicle performance and ensure long-term reliability under varied operating conditions.

Custom Automotive Solutions Through CNC Machining Services

CNC machining allows manufacturers to respond to specialised vehicle requirements through flexible tooling and software-based programming. Adaptability in production suits unique automotive applications, from electric retrofits to motorsport modifications.

• Precision for One-Off Builds: Enables accurate manufacturing of single-unit or prototype components that meet the dimensional and functional needs of custom vehicle projects.

• Integration of Non-Standard Designs: Supports the creation of complex geometries and alternative configurations that fall outside traditional automotive part specifications.

• Adaptive Programming for Evolving Requirements: Allows modifications to machining parameters to accommodate design updates, performance demands, or technological changes during development.

• Material Flexibility for Custom Applications: Accommodates a broad range of alloys, plastics, and composites selected specifically for performance, durability, or aesthetic purposes.

• Tolerance Control in Custom Fabrication: Maintains exact tolerances to ensure components align with unconventional chassis layouts, drivetrain setups, or bespoke assemblies.

• Support for Electrification and Hybrid Upgrades: Facilitates the production of tailored parts required in electric vehicle conversions or hybrid adaptations, maintaining mechanical and regulatory integrity.

• Surface Finish Adaptability: Provides varied finishing options to suit visual preferences or functional surface treatments required for custom automotive applications.

Delivering Reliable Precision for Melbourne’s Automotive Sector

Through a commitment to accuracy and compliance, Semtool Engineering delivers CNC machining aligned with the complex manufacturing requirements of today’s automotive projects. Our systems are structured to uphold industry specifications while offering adaptable production frameworks for niche applications.

Discover how our CNC machining offerings support compliant and precision-focused builds. Contact us for a consultation tailored to your production objectives.

Related Content: CNC Machining Services: Their Significance in Precision Engineering

Read about the Automotive ADR Testing and Compliance processes that govern vehicle design, performance, and safety standards across Australia’s transport sector.