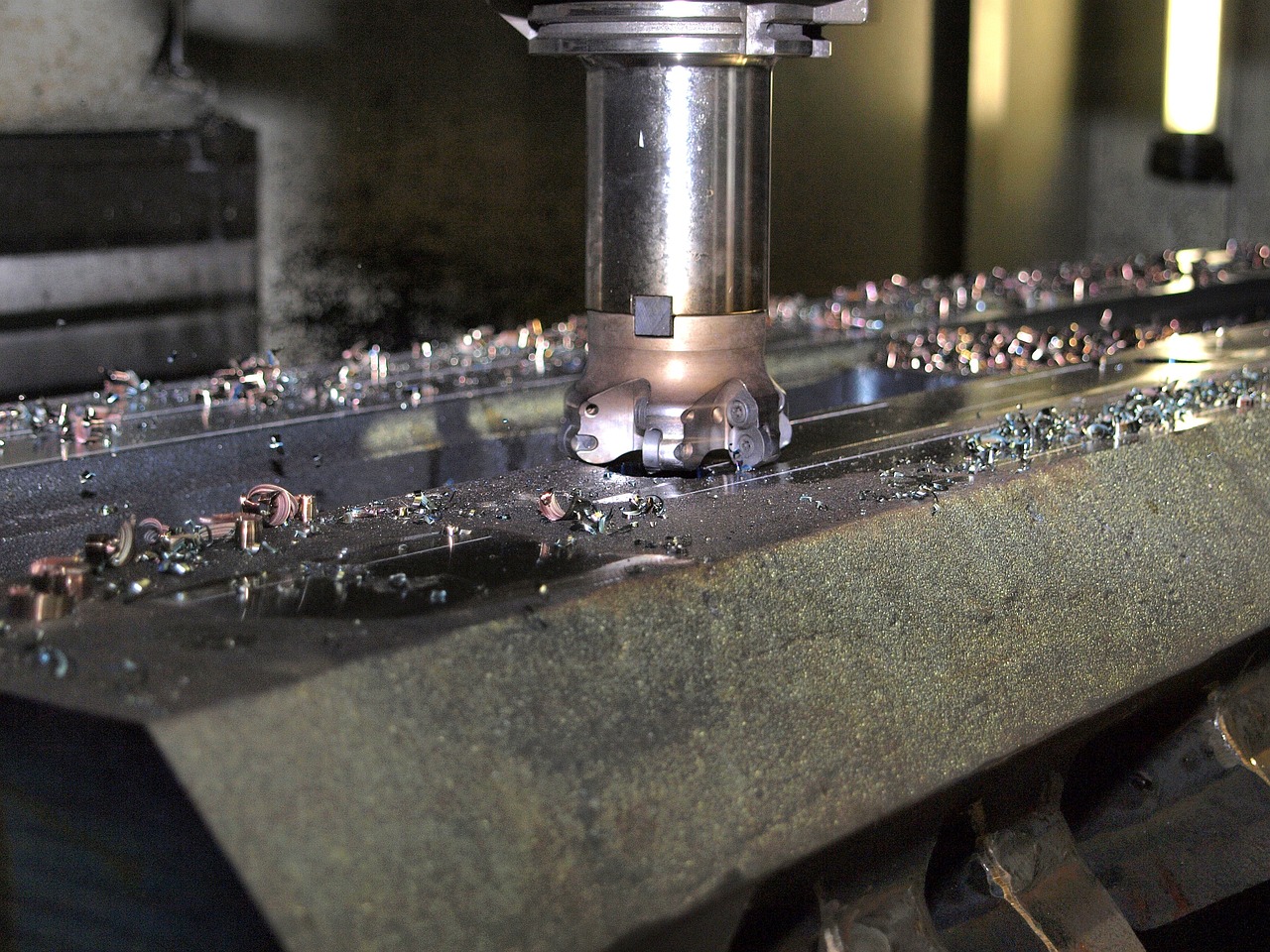

Create intricate designs with precision through CNC milling by Semtool Engineering. Enhance overall product quality across various industries in Melbourne.

At Semtool Engineering, CNC milling enables us to craft intricate designs with exceptional precision. Our advanced CNC milling technology allows us to produce complex geometries and detailed features across a wide range of materials, ensuring the highest quality standards for various applications.

With a commitment to innovation and efficiency, Semtool Engineering harnesses the power of CNC milling to deliver tailored solutions that meet the unique needs of our clients.

The Working Principles of CNC Milling

The working principles of CNC milling are straightforward.

First, CNC milling works by rotating a cutting tool, which removes material from a solid block of material (such as metal, plastic, or wood) in a controlled manner. The tool then moves along multiple axes to achieve the desired shape and dimensions.

The movement of the milling machine has been programmed using a CAD (Computer-Aided Design) file, which is translated into a set of instructions (G-code) that the CNC machine follows. This ensures high accuracy and repeatability in the milling process.

Craft Intricate Designs with CNC Milling

Crafting intricate designs with CNC milling is a powerful capability that has transformed various industries, including aerospace, automotive, medical, and consumer products. The precision and flexibility of CNC milling machines allow designers and engineers to produce complex shapes and detailed features that would be difficult or impossible to achieve with traditional manufacturing methods.

Here’s why CNC milling can be useful in creating parts with intricate designs:

• Tight Tolerances: CNC milling machines can achieve high levels of accuracy and repeatability, allowing for the production of parts with tight tolerances. This precision is crucial for intricate designs that require exact specifications and fitting.

• Consistent Quality: The automated nature of CNC milling ensures that each part is produced to the same high standard, reducing variability and enhancing the overall quality of intricate components.

• Multi-Axis Machining: Advanced CNC milling machines, such as 5-axis mills, can manipulate the workpiece and cutting tool along multiple axes simultaneously. This enables the production of intricate designs with undercuts, slopes, and varying depths that would be challenging to achieve with 3-axis milling.

• Material Versatility: CNC milling can exploit the properties of different materials like metals, plastics, and composites, allowing for intricate designs that take advantage of factors like weight distribution, thermal conductivity, and mechanical strength.

• Fine Detail Work: CNC milling can produce intricate patterns, engravings, and surface textures that enhance the aesthetics and functionality of a product. This level of detail is often required in industries like jewellery design, where precision is paramount.

Primary Applications of CNC Milling

There are many applications in various industries that can take advantage of CNC milling when crafting parts with intricate designs.

The aerospace and automotive industries, for instance, can use CNC milling to produce intricate components like brackets, housings, and structural parts. CNC milling can also be useful in creating complex geometries for medical devices and implants, where precision and functionality are vital for patient safety and device performance.

From custom tooling to intricate designs in gadgets and household items, CNC milling likewise allows manufacturers to produce visually appealing and functional consumer products.

CNC milling empowers designers and manufacturers to craft intricate designs with exceptional precision, versatility, and efficiency. Need help with CNC milling? Contact us at Semtool Engineering so we can carry out this process for crafting intricate designs.