Semtool Engineering offers custom cylindrical grinding for automotive components in Melbourne. Get precision, durability, and a competitive quote today.

Custom cylindrical grinding is a vital service in the automotive sector, where component precision is non-negotiable. In Australia’s competitive manufacturing landscape, tailored grinding solutions are essential for ensuring quality, performance, and cost-effectiveness. Semtool Engineering partners with automotive manufacturers to deliver perfectly machined components that meet strict industry standards and assembly requirements.

The Value of Custom Cylindrical Grinding for Automotive Parts

Precision-ground components are the backbone of modern vehicle performance. By choosing custom grinding solutions, manufacturers benefit from:

• Enhanced Accuracy: Each gear, shaft, and engine part is crafted to tight tolerances, ensuring a perfect fit and minimal vibration.

• Superior Surface Finish: Smoother finishes reduce friction and wear, promoting longevity.

• Improved Performance: High-precision components lead to better thermal control and fuel efficiency.

• Minimised Downtime: Custom solutions reduce production errors, eliminating costly rework and delays.

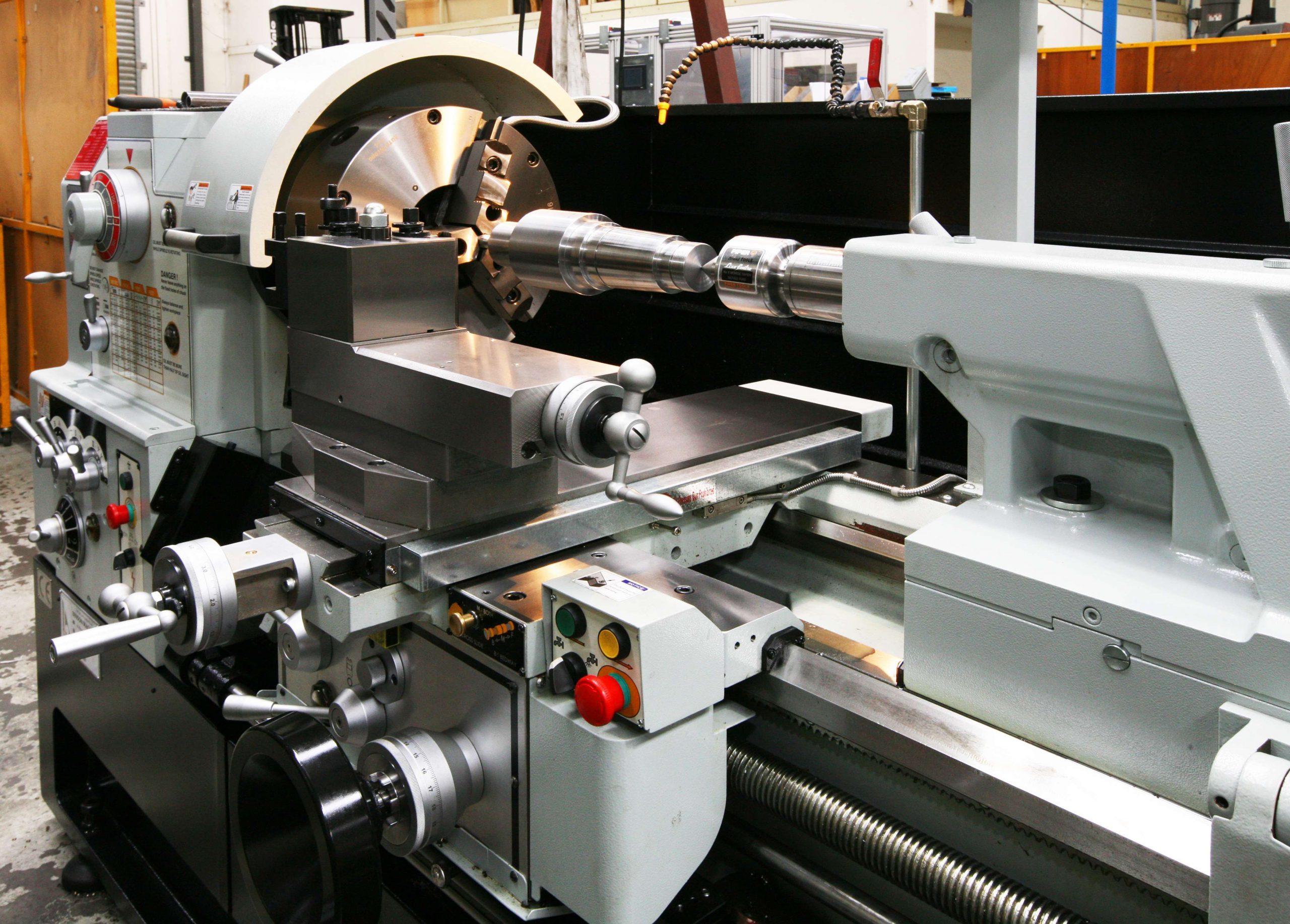

Innovations in Cylindrical Grinding Technology

To remain a leader in precision engineering, Semtool Engineering embraces the latest in cylindrical grinding advancements:

• CNC Automation: Our CNC grinding equipment delivers consistent, repeatable results at scale.

• Next-Gen Abrasives: We use cutting-edge abrasive materials for superior surface finishes and reduced part stress.

• Real-Time Quality Monitoring: Integrated sensors and software track tool wear and part conformity in real time.

• High-Speed Grinding Solutions: Optimised speed and coolant management improve productivity without compromising precision.

These innovations enable us to meet the demands of high-performance vehicles and evolving industry standards.

Why Choose Semtool Engineering for Cylindrical Grinding?

We don’t just provide grinding—we deliver engineering excellence. Here’s what sets us apart:

• Specialisation in Diverse Metals & Alloys: From aluminium to hardened tool steels, we handle complex materials with ease.

• Tight Tolerance Expertise: We consistently meet demanding specifications required for critical automotive components.

• Advanced Machinery: Our workshop is equipped with state-of-the-art cylindrical grinding equipment and CAD/CAM software.

• Custom Solutions: We solve complex grinding challenges through tailored approaches and experienced technical support.

• Fast Turnarounds: Efficient processes and a skilled team mean we meet urgent production timelines.

• Strict Quality Assurance: Our QA protocols ensure every component is inspected, verified, and ready for assembly.

Applications in the Automotive Sector

Semtool Engineering provides cylindrical grinding for a wide range of automotive components, including:

• Engine shafts and crankshafts

• Gearbox and transmission parts

• Hydraulic piston rods

• Custom spindles and rollers

Each component is machined with care to ensure seamless integration into modern automotive systems.

Get a Competitive Quote Today

Semtool Engineering leads the way in custom cylindrical grinding and precision manufacturing. From concept to production, our Melbourne-based team is committed to quality, efficiency, and customer satisfaction.

Ready to experience the difference of precision-ground automotive parts?

Contact us today for a competitive quote on custom cylindrical grinding services.

Related Blog Article:

• CNC Machining Services in Melbourne for Compliant & High-Precision Automotive Manufacturing

Additional Reading:

• Universal Grinding Corporation: What is Cylindrical Grinding

• What is Grinding Machine: Definition and Types – Engineering Choice