Explore cutting-edge CNC machining techniques transforming defence applications, including multi-axis, high-speed, automated, and hybrid manufacturing.

CNC machining techniques are revolutionising the landscape of advanced defence applications, providing unparalleled precision and efficiency in manufacturing. As the demand for high-performance components grows, innovative methods such as multi-axis machining and additive manufacturing are becoming essential. These cutting-edge techniques not only enhance production capabilities but also ensure the reliability and effectiveness of defence systems.

Innovative CNC Machining Techniques

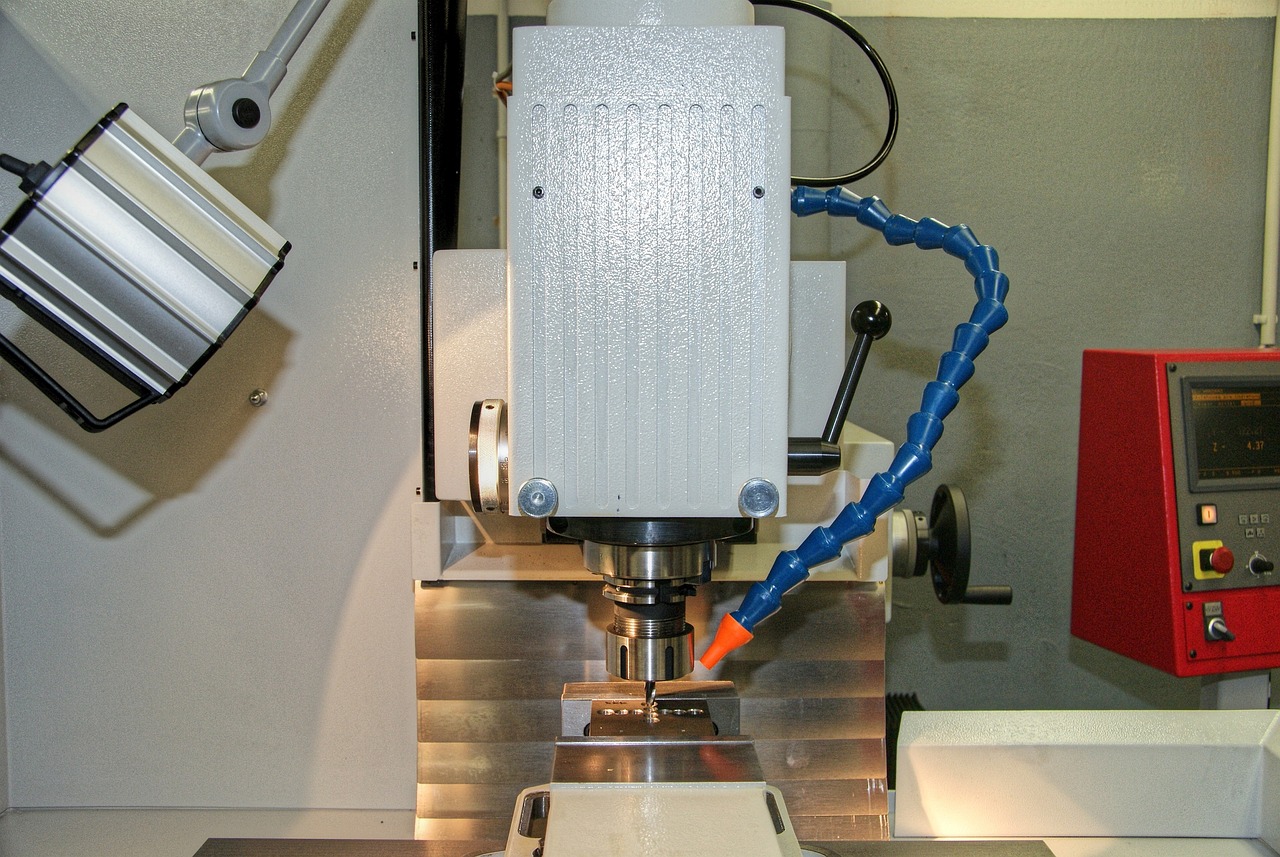

CNC machining has evolved significantly in recent years, incorporating innovative techniques that have transformed the defence industry. These advanced methods offer enhanced precision, efficiency, and versatility, enabling the production of complex and high-quality components. Let’s explore some of the key techniques driving innovation in defence manufacturing:

• Multi-Axis Machining: Multi-axis machining is a game-changer in the defence sector, allowing for the creation of complex geometries and intricate designs in a single setup. By utilising up to 9 axes, multi-axis CNC machines can produce parts with exceptional accuracy and consistency, reducing the need for multiple processes and minimising the risk of errors.

• High-Speed Machining: High-speed machining (HSM) is another technique that has significantly improved production rates without compromising precision. By using specialised cutting tools and optimised machining parameters, HSM enables aggressive material removal rates while maintaining tight tolerances. This is particularly beneficial for meeting tight deadlines and high-volume demands in the defence industry.

• Automated Machining: Automated machining is a crucial technique for enhancing efficiency and consistency in defence manufacturing. By integrating robotic systems with CNC machines, the process can be streamlined, reducing human error and increasing production speed. This ensures that each batch of components meets the same high standards, contributing to the overall reliability and performance of defence systems.

• Additive Manufacturing: Additive manufacturing, commonly known as 3D printing, is an innovative technique that is gaining traction in the defence sector. By building parts layer by layer, additive manufacturing allows for the creation of complex geometries that would be difficult or impossible to produce using traditional machining methods. This technique is particularly useful for rapid prototyping and the production of low-volume, customised parts.

• Hybrid Manufacturing: Hybrid manufacturing combines the benefits of additive manufacturing and CNC machining to create a powerful tool for defence applications. By using additive manufacturing to create near-net-shape parts and then using CNC machining to finish and refine the components, hybrid manufacturing can produce parts with exceptional accuracy and surface finish. This technique is particularly useful for creating parts with complex internal features or for repairing or refurbishing existing components.

• Advanced Material Machining: As the defence industry continues to explore new materials such as carbon fibre composites and high-strength alloys, advanced CNC machining techniques have been developed to handle these challenging materials. Techniques such as ultrasonic machining and laser-assisted machining are now being used to produce components that are lighter, stronger, and more durable than ever before.

Whether you require prototype development, low-volume production, or high-volume manufacturing, Semtool Engineering is your trusted partner for precision CNC machining in the defence sector. Contact us for more information.