Deliver reliable medical R&D outcomes using medical engineering components by Semtool Engineering, trusted in Melbourne for precision solutions.

Medical engineering components drive functionality across research and development processes through micro-level machining and scalable fabrication solutions. These precision-manufactured parts support innovation by enabling repeatable, reliable performance within prototyping, clinical instrumentation, and device trials.

Applications of Medical Engineering Components in R&D

Prototyping activities in medical research rely on precisely machined components to simulate working device systems under controlled testing conditions. These allow project teams to refine mechanical configurations while capturing consistent trial data.

Medical engineering components also streamline the development of diagnostic tools by supporting iterative testing. The durability and adaptability of parts allow for successive modifications without compromising structural performance or measurement consistency.

Tolerances and Accuracy in Medical Engineering Components

Tight dimensional tolerances enable the creation of highly accurate surgical and diagnostic instruments. Components are machined to specifications within micron-level thresholds, reducing calibration drift and ensuring device integrity throughout repeated use.

Accuracy also supports consistency in biomedical device assembly. Precision parts maintain alignment and functionality across miniaturised systems, especially where internal mechanisms interact with biological tissues or reactive fluids under stringent conditions.

Miniaturisation Trends in Medical Engineering Components

Miniaturisation influences both performance and usability of contemporary medical innovations. Components fabricated at smaller scales enable seamless integration into portable or implantable devices.

• Improved Portability: Lightweight, compact designs allow advanced diagnostic equipment to be utilised in off-site or point-of-care settings, without compromising operational accuracy.

• Reduced Invasiveness: Smaller surgical tools and implants reduce procedural trauma. Precision machining ensures optimal edge geometry and fits across varying anatomical conditions.

• Increased Device Complexity: High-resolution internal structures support complex functionalities in constrained physical spaces. These enable multi-stage diagnostic processes within compact units.

• Enhanced Integration: Components work in conjunction with smart sensors, improving feedback mechanisms and real-time adaptability in medical instruments.

• Greater Energy Efficiency: Miniaturised systems require lower energy input for equivalent output. This improves battery life and long-term functionality, especially in mobile biomedical tools.

Precision-Led Outcomes Through Semtool Engineering

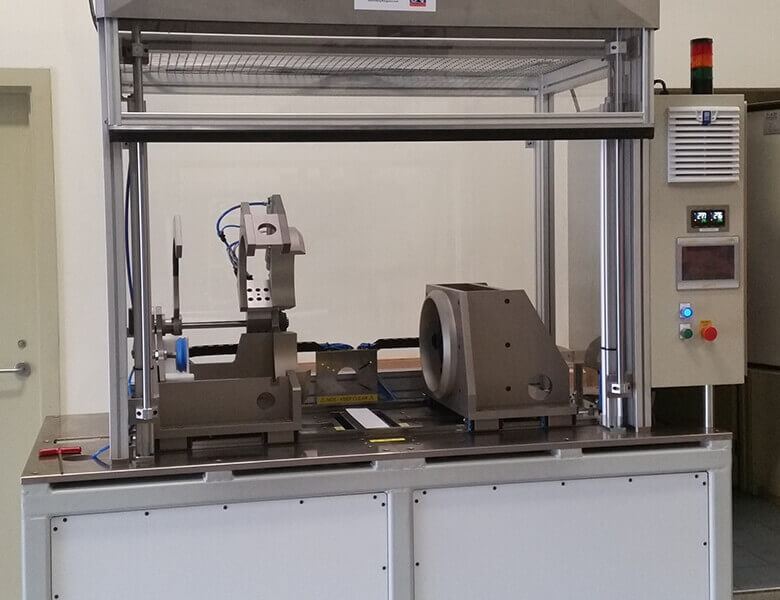

Demonstrating consistent output across machining projects, Semtool Engineering delivers precision parts tailored to the intricate demands of medical R&D. As a partner in innovation, our expertise in designing and fabricating functional components ensures seamless integration into high-performance diagnostic assemblies and scalable instruments.

Explore refined precision machining solutions tailored to research and development in the medical sector through Semtool Engineering’s dependable manufacturing systems.

Learn how medical equipment moves from research to full-scale manufacturing in this clear and practical guide:

Medical Equipment Manufacturing: How to Scale from R&D to Full Commercialization