Learn when to use milling vs turning with expert guidance from Semtool Engineering, delivering accurate, efficient CNC machining in Melbourne.

The decision between milling vs turning directly influences the precision, efficiency, and overall cost of producing a component. CNC machining offers multiple processes, each suited to specific shapes and functional requirements. Understanding the differences between these two methods helps determine the best approach based on geometry, material removal, production speed, and budget.

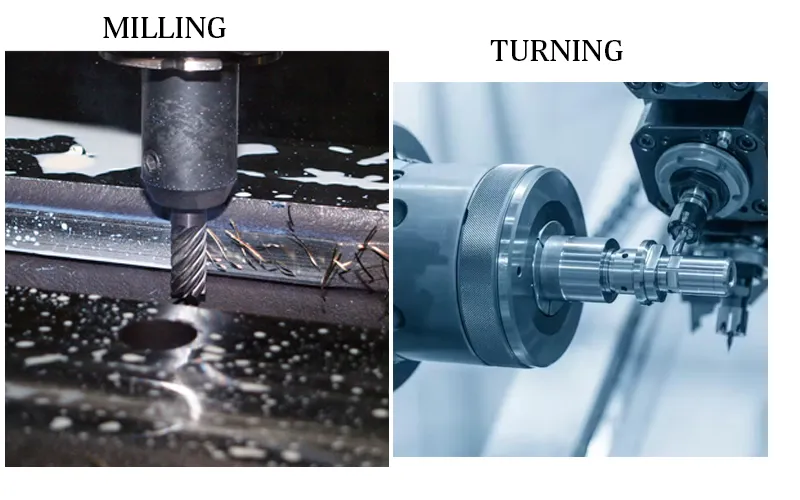

Milling and Turning Explained: Core CNC Processes

Milling is a subtractive machining process where cutting tools move along multiple axes to shape a stationary workpiece. It is ideal for creating flat surfaces, slots, pockets, and detailed contours with high precision. This method is well-suited for producing complex components that require accuracy and fine surface finishes.

Turning involves rotating the workpiece while a single-point cutting tool removes material to form the desired shape. It is highly efficient for manufacturing cylindrical parts such as shafts, bushings, and threaded components. While both processes remove material with precision, milling is better for multi-surfaced designs, whereas turning excels at creating round or symmetrical geometries.

Key Geometry Factors to Consider

The geometry of a component is the most critical factor when selecting the right CNC process. Each feature influences tooling choice, setup time, and achievable tolerances.

Key considerations include:

• Length vs Diameter: Long, slender components with consistent diameters are typically suited for turning, while wider parts with varying profiles work better with milling.

• Profile Complexity: Flat surfaces, slots, and cavities are ideal for milling, whereas smooth curves and round profiles align with turning processes.

• Tolerances: High-precision requirements demand stable setups. Turning often provides tighter concentricity, while milling excels in intricate detail work.

• Surface Finish: When superior surface smoothness is necessary, turning generally produces a finer finish on cylindrical parts.

• Material Considerations: The hardness and machinability of the material affect tooling wear and cycle times, influencing process choice.

Comparing Milling vs Turning According to Geometry Scenarios

Components that are primarily round or tubular are best suited to turning. This process delivers smooth, consistent shaping while maintaining tight tolerances along the entire part.

Parts with multiple flats, pockets, holes, or detailed cut-outs benefit more from milling. Hybrid geometries may require both processes or advanced multi-axis machines to achieve precise results with minimal handling.

Partner with Semtool Engineering for Precision Results

At Semtool Engineering, selecting between milling vs turning is guided by the specific geometry, complexity, and functional requirements of each component. The right process is critical to achieving precision, efficiency, and reliable performance.

Our advanced machining services cover CNC milling and turning, supported by large lathes with a diameter capacity of 650mm and a bed length of 2500mm. Through expert assessment, reverse engineering, and customised strategies, every part is manufactured to meet strict quality and industry standards.

Contact us at Semtool Engineering today to discuss your project and meet your specifications.

Related Blog Articles:

CNC Milling by Semtool Engineering for Crafting Intricate Designs

Reverse Engineering with Turning Machines: Bring Back Legacy Components