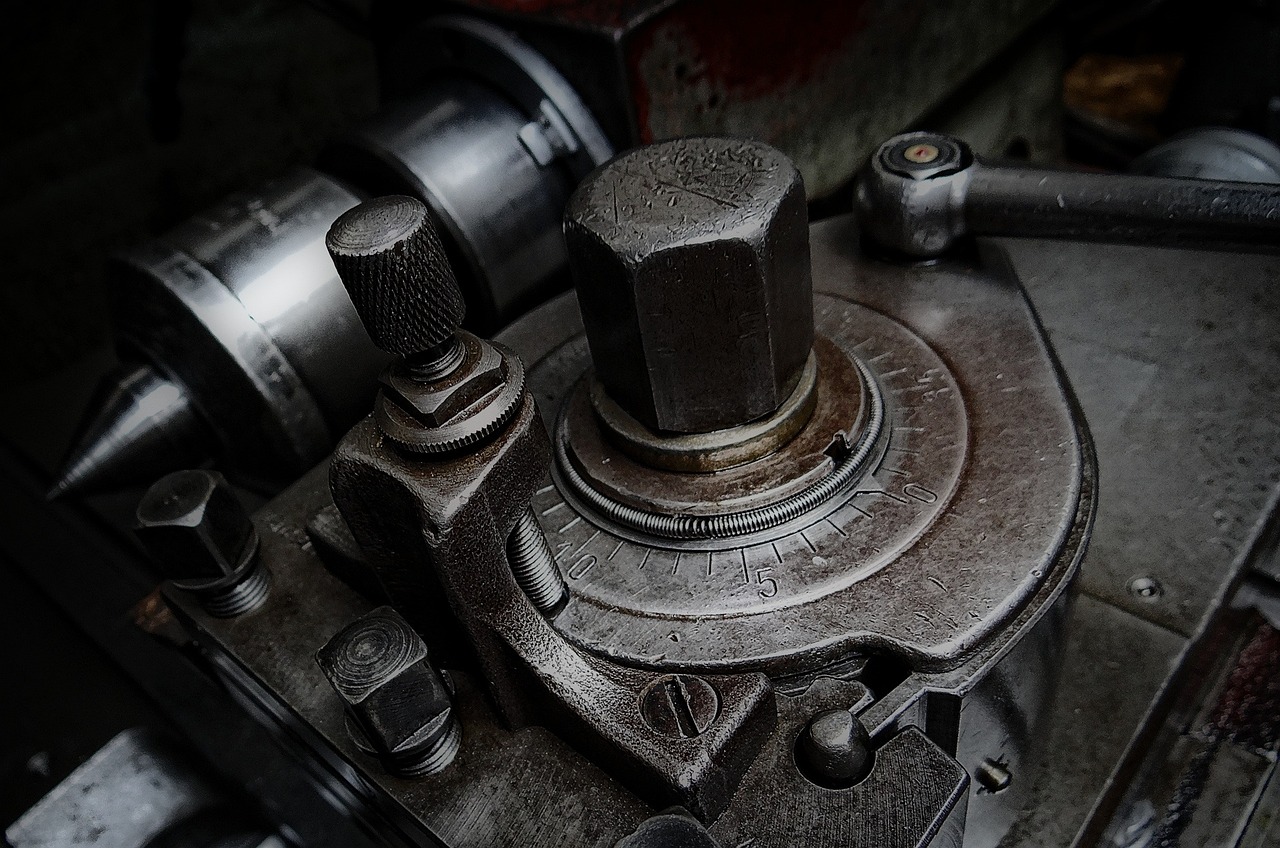

CNC lathe technology from Semtool Engineering ensures efficiency and precision, making it ideal for modern high-performance manufacturing needs.

CNC lathe technology achieves intricate geometries with unparalleled dimensional stability. Sophisticated numerical controls maintain consistent tolerances, even across complex machining cycles. This process delivers components with exacting specifications, vital for high-performance applications.

Beyond Speed: The Efficiency and Accuracy of CNC Lathe Technology

Advanced automation protocols minimise human error, ensuring uniform product quality. Integrated CAD/CAM systems translate complex designs into precise machine instructions, streamlining the production workflow. Tool path optimisation algorithms reduce machining time, improving overall operational throughput.

Pre-programmed sequences guarantee repeatable accuracy for large-scale production runs. Real-time sensor feedback enables immediate adjustments, maintaining stringent quality standards. Material utilisation is maximised through efficient cutting strategies, minimising waste and reducing operational costs.

Innovation in Motion: Why CNC Lathe Technology Leads Modern Engineering

Sophisticated programming algorithms optimise cutting paths, thereby reducing material waste and enhancing surface quality. Integrated real-time feedback systems facilitate immediate adjustments, ensuring consistent production of high-precision components.

The incorporation of AI-driven tools predicts potential tool wear, minimising downtime and maximising production efficiency. Comprehensive data analysis enables predictive maintenance, ensuring continuous operation and mitigating unexpected disruptions.

Read this blog for more advanced information: How CNC Machining is Impacting Modern-Day Manufacturing? An Expert View

Shaping the Future: CNC Lathe Technology in High-Precision Industries

Precision manufacturing, driven by advanced CNC lathe technology, defines the contemporary landscape of high-demand sectors. The capacity to produce intricate components with exacting tolerances enables industries to achieve previously unattainable levels of performance and reliability.

• Aerospace: Operational reliability in extreme conditions is achieved through the manufacture of critical aerospace components with exacting tolerances.

• Medical Device Manufacturing: Precision machining of biocompatible implants and surgical tools via CNC lathes enhances patient outcomes through improved fit and procedural accuracy.

• Automotive: Automated lathes contribute to the creation of high-performance automotive components, optimising engine efficiency and reducing emissions.

• Oil and Gas: Robust and precise components manufactured with CNC lathes are essential for withstanding the harsh conditions found in oil and gas extraction.

• Electronics: Reliable connectivity and thermal management are ensured through the production of intricate electronic components.

• Defence: High-precision CNC machining is vital for manufacturing reliable and accurate defence components, ensuring operational effectiveness.

• Tool and Die Manufacturing: The manufacturing of complex and precise parts across various industries is enabled by highly accurate moulds, dies, and cutting tools.

Precision Engineering: Semtool Engineering’s Commitment

Acknowledging the requirements of modern production, Semtool Engineering utilises advanced CNC lathe technology. We deliver precise components, meeting strict industry standards. This focus on accuracy establishes us as a reliable partner in Melbourne’s engineering sector.

Review the range of industrial and commercial services, designed to meet project specifications.

Support your knowledge with our related blog: CNC Machining Services: Their Significance in Precision Engineering