Semtool Engineering delivers PLC automation services designed to enhance control accuracy and system efficiency for Melbourne industries in 2026.

Industrial systems entering 2026 demand higher precision, smarter sequencing and improved reliability, making PLC automation services critical for efficient control. Engineered automation frameworks help facilities stabilise processes and maintain consistent performance under varying operating conditions. These advancements support modern production environments that require accuracy, repeatability and dependable long-duty operation.

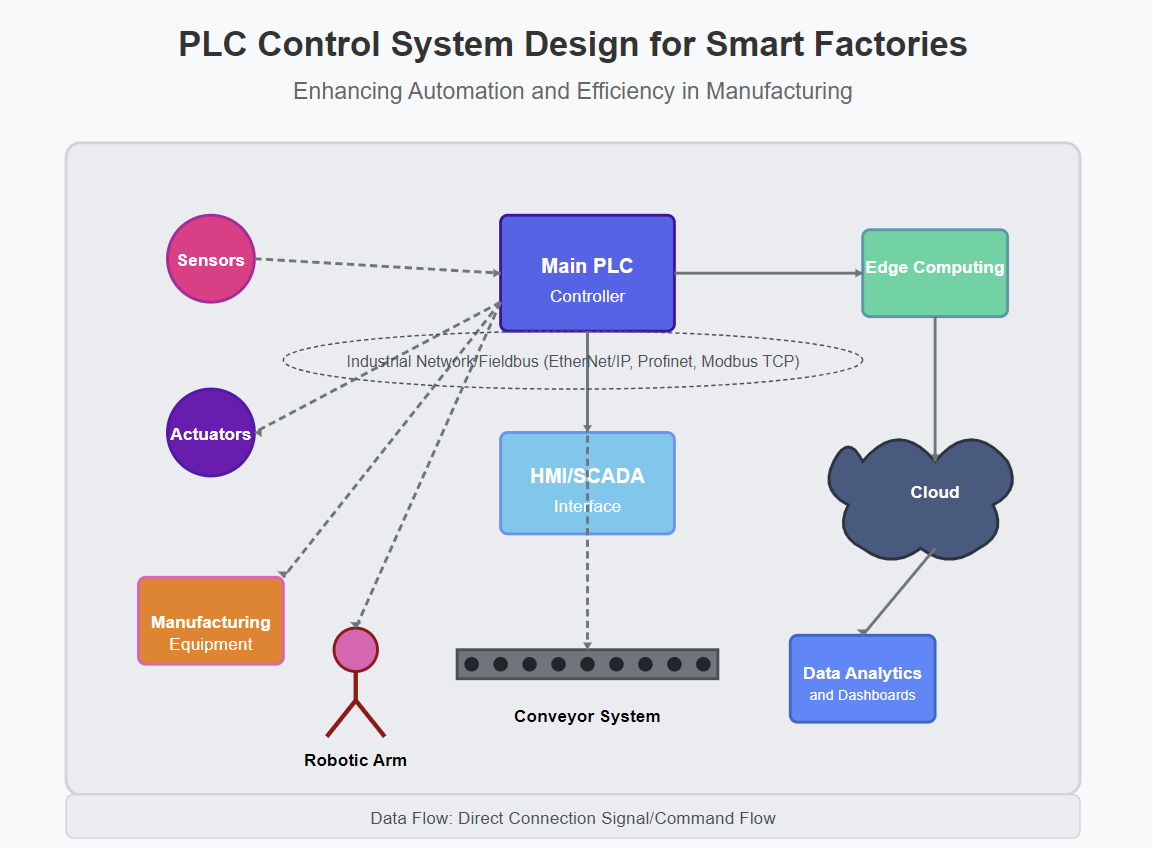

Integrated System Architecture for Intelligent Industrial Control

Engineers deploy programmable logic solutions to manage sequencing, monitoring and coordination across complex production lines. Structured control methodologies improve communication between sensors, actuators and supervisory systems, resulting in smoother transitions and reduced operational variance. This integrated architecture supports predictable responses that enhance throughput and machine stability.

PLC automation services increasingly rely on modular platforms capable of expansion without extensive redesign. Facilities benefit from flexible configurations that handle additional I/O points, advanced control logic and future equipment upgrades. Scalable hardware frameworks reduce disruption while enabling continuous improvements in precision and operational efficiency.

Data Driven Intelligence in PLC Automation Services

Operations teams seek analytics-driven control strategies that enhance sequencing accuracy and reduce mechanical inconsistencies. Modern automation environments utilise processed data streams to validate cycle performance, identify inefficiencies and strengthen the reliability of continuous duty equipment supported by PLC automation services. These solutions contribute to refined industrial intelligence and stronger operational outcomes.

The study on Optimization and Innovation of Industrial Control Systems Based on PLC provides peer-reviewed research on how PLC-driven optimisation improves responsiveness, accuracy and system coordination. The findings reinforce the value of advanced data integration practices that elevate situational awareness and support stable performance across complex industrial networks.

Key Advantages of Advanced Control Systems

Industrial facilities adopting modernised control systems achieve stronger performance metrics and stability across variable operating conditions. Each benefit contributes to smoother, more predictable output.

• Scalable Hardware Expansion: Facilities gain long-term flexibility through modular configurations that accommodate future equipment or system growth without major rework.

• High Reliability Sequencing Accuracy: Engineered logic pathways deliver consistent cycle performance, ensuring stable operation across varying production demands.

• Improved Lifecycle Efficiency: Refined control strategies reduce mechanical load and operational stress, extending equipment service life while maintaining system stability.

• Optimised Communication Protocols: Enhanced interoperability between devices supports smoother data exchange, improving coordination across interconnected automation layers.

• Operational Data Visibility: Advanced monitoring provides real-time insights into system conditions, enabling rapid adjustments and informed decision-making.

Future Ready Control Solutions for Australian Industry

At Semtool Engineering, we support Australian businesses aiming to enhance automation efficiency through tailored PLC logic design, engineered control architecture and high-performance PLC automation services. Our solutions help facilities improve system reliability and maintain steady performance across demanding operating conditions. These advancements position operations for stronger capability in 2026, supporting more resilient control outcomes across evolving industrial demands.

Contact us to discuss advanced solutions for your industrial environment.

Related Blog Article: PLC Programming Services: Custom Control Systems for Production Lines