Transform smart factory operations through PLC control system design by Semtool Engineering, improving automation and manufacturing precision.

PLC control system design revolutionises manufacturing by enabling seamless automation and improved efficiency. Businesses benefit from streamlined operations, reduced costs, and enhanced precision when integrating PLC systems into their production processes.

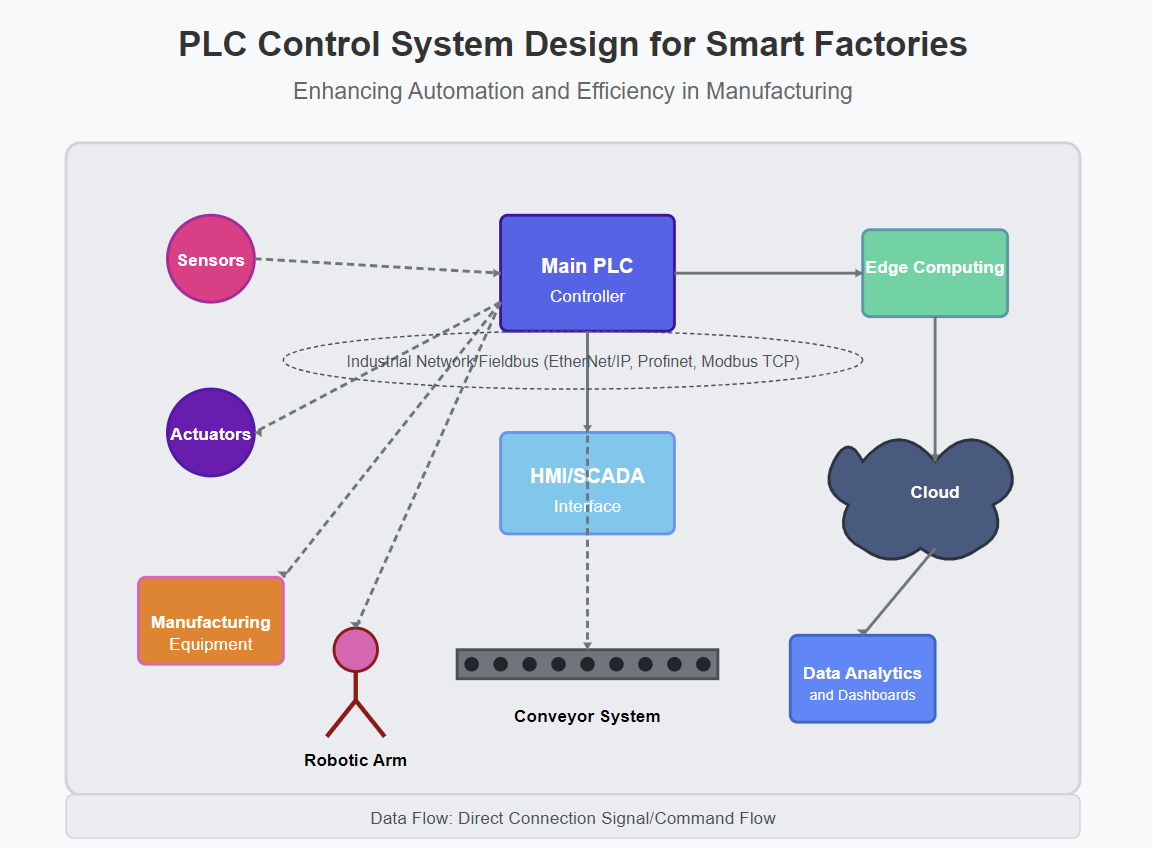

Integrating PLC Control System Design with Smart Technologies

Programmable Logic Controllers (PLCs) serve as the foundation of automation systems in manufacturing. Their integration with technologies like artificial intelligence, robotics, and cloud computing enhances efficiency and adaptability.

Artificial intelligence enables PLC systems to analyse real-time data, improving predictive maintenance and operational decisions. Robotics paired with PLC automates repetitive tasks, ensuring consistent productivity and reducing errors in manufacturing processes.

Cloud computing allows PLC systems to be monitored and controlled remotely, providing operators with access to real-time insights. This connectivity optimises workflows and positions businesses for growth in competitive manufacturing environments.

How PLC Control System Design Improves Automation & Productivity

Automation powered by PLC systems reduces downtime while ensuring precision control over manufacturing processes. Businesses achieve greater reliability in operations through streamlined workflows and optimised resource utilisation.

• Operational Efficiency: PLC systems enable faster production cycles by automating repetitive tasks and reducing delays. This ensures consistent output while minimising bottlenecks in manufacturing workflows.

• Enhanced Accuracy: Precision control mechanisms reduce errors, ensuring products meet exact specifications. This improves overall quality while reducing waste during production processes.

• Real-Time Monitoring: PLCs provide instant feedback on equipment performance, allowing operators to make adjustments promptly. This prevents disruptions and maintains smooth operations across all stages of manufacturing.

• Predictive Maintenance: Advanced algorithms predict potential equipment failures before they occur, minimising downtime and repair costs. This proactive approach ensures uninterrupted productivity.

• Scalability: PLC systems adapt easily to growing business needs, making them suitable for expanding operations or new projects. Their flexibility supports long-term growth without compromising efficiency.

• Improved Safety: Automation reduces the risk of human error in hazardous tasks, creating safer working environments for employees. This fosters compliance with safety regulations while protecting workers’ well-being.

• Data Insights: PLC systems collect valuable data that can be analysed to identify trends and improve processes over time. Businesses use these insights to drive innovation and maintain competitiveness.

• Quality Assurance: Continuous monitoring ensures products consistently meet high standards of quality, boosting customer satisfaction and brand reputation in competitive markets.

• Energy Optimisation: Automated processes reduce energy consumption by ensuring machines operate at optimal levels. This contributes to sustainability goals while lowering operational expenses.

Strengthening Manufacturing with Semtool Engineering

In light of the advancements in manufacturing technology, Semtool Engineering stands out for its commitment to delivering exceptional PLC control system design solutions. Our innovative approach empowers businesses to thrive by enhancing automation and efficiency in smart factories.

Explore our superior solutions that enable your operations to reach new heights of success.

Acquire additional enhanced information by reading this blog: How PLC Programming Drives Efficiency in Smart Factories.