Advance your manufacturing with Semtool Engineering in Melbourne, delivering precision prototypes & tooling, machining, and automation expertise.

Melbourne has long been recognised as a hub for advanced industrial manufacturing, where businesses demand accuracy, reliability, and efficiency at every stage of production. At Semtool Engineering, we deliver precision prototypes and tooling that enable manufacturers to innovate while maintaining strict performance standards. Combined with industrial machining and automation, our solutions support the development of high-quality products across competitive sectors.

What Are Precision Prototypes & Tooling?

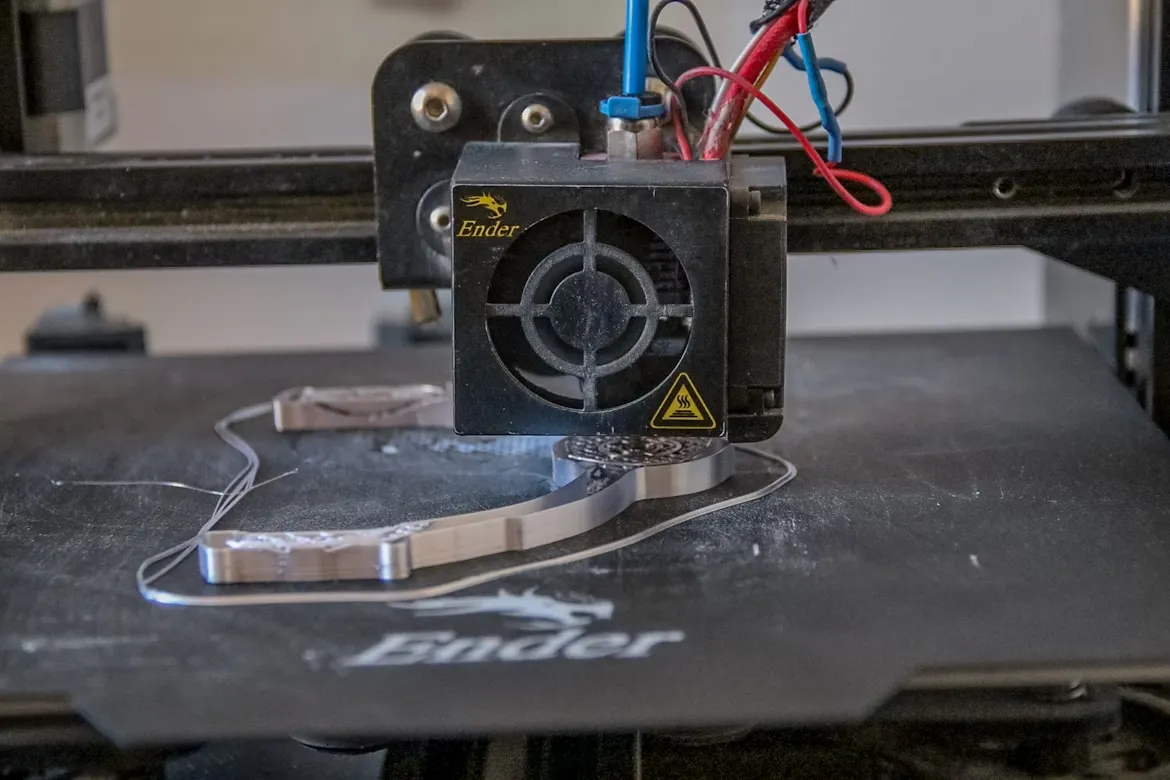

Prototypes serve as the bridge between design concepts and finished products, allowing engineers to test functionality, uncover design flaws, and refine performance before moving to large-scale production. This process reduces risks, shortens development cycles, and ensures that end products meet demanding industry standards.

Specialised tooling supports mass production by delivering accuracy and consistency across thousands of components. Precision engineering solutions guarantee exact tolerances, enabling industries with strict safety and compliance requirements to achieve reliable and efficient manufacturing outcomes.

Key Industries in Melbourne That Rely on These Solutions

Across Melbourne, several industries rely on prototypes and tooling to strengthen production standards. These sectors demand precision, scalability, and adaptability, making tailored machining solutions indispensable.

• Aerospace: Components in aircraft structures require absolute dimensional accuracy. Prototyping enables testing under extreme conditions, while tooling guarantees safe, repeatable production at scale.

• Automotive: From drivetrain assemblies to interior systems, manufacturers depend on robust tooling to deliver reliability. Prototypes shorten development cycles and improve cost-efficiency in high-volume production.

• Defence: Military-grade equipment must meet strict compliance benchmarks. Prototyping validates performance, while tooling secures repeatability for mission-critical systems.

• Medical: Surgical instruments and implants demand exceptional precision. Prototypes allow thorough validation, while specialised tooling enables sterile, compliant mass manufacturing.

According to Precedence Research’s Tooling Market Study, the global tooling market is expected to grow from USD 273.89 billion in 2024 to more than USD 531.62 billion by 2034, highlighting the accelerating demand for precision prototypes and tooling worldwide. This growth positions Melbourne manufacturers, supported by Semtool Engineering, to capitalise on advanced machining and automation solutions.

Industrial Machining – The Backbone of Precision Engineering

Industrial machining forms the backbone of precision engineering, with CNC milling, turning, grinding, and related processes transforming raw materials into high-performance components. These technologies achieve exact tolerances and finishes while delivering repeatability, efficiency, and reduced lead times that manual methods cannot match. By enabling consistent prototype production, machining continues to reinforce Melbourne’s reputation as a leader in advanced precision engineering.

Automation in Manufacturing – Boosting Productivity

Automation is reshaping modern manufacturing by enabling smarter, faster, and more precise production processes. With robotics, AI, and advanced control systems, manufacturers in Melbourne are achieving higher output and greater adaptability to meet evolving market demands.

• Increased efficiency through uninterrupted machining and consistent product quality

• Reduced labour costs by automating repetitive and time-intensive tasks

• Improved workplace safety by minimising exposure to hazardous operations

• Enhanced scalability to easily adjust production volumes in response to demand

• Optimised resource use with better energy management and reduced material waste

Semtool Engineering – Specialists in Precision Prototypes & Tooling

Semtool Engineering provides precision prototypes and tooling services that help businesses bring concepts to life with exceptional accuracy and efficiency. From custom machine design to advanced automation, we deliver solutions that streamline production and address complex manufacturing challenges. We work closely with our clients to develop tailored systems that drive innovation and long-term growth.

Contact us to learn how our expertise can support your next project.

Related Blog Article: How Tool Design and Manufacturing Impact Production Quality