Production tooling design by Semtool Engineering offers custom jigs and fixtures to optimise efficiency and reduce errors in manufacturing processes.

Production tooling design plays a pivotal role in enhancing manufacturing efficiency and precision. Integrating custom jigs and fixtures optimises workflows, ensuring consistent quality and minimising errors. This approach significantly improves both time and cost efficiency, providing manufacturers with reliable solutions for complex production tasks.

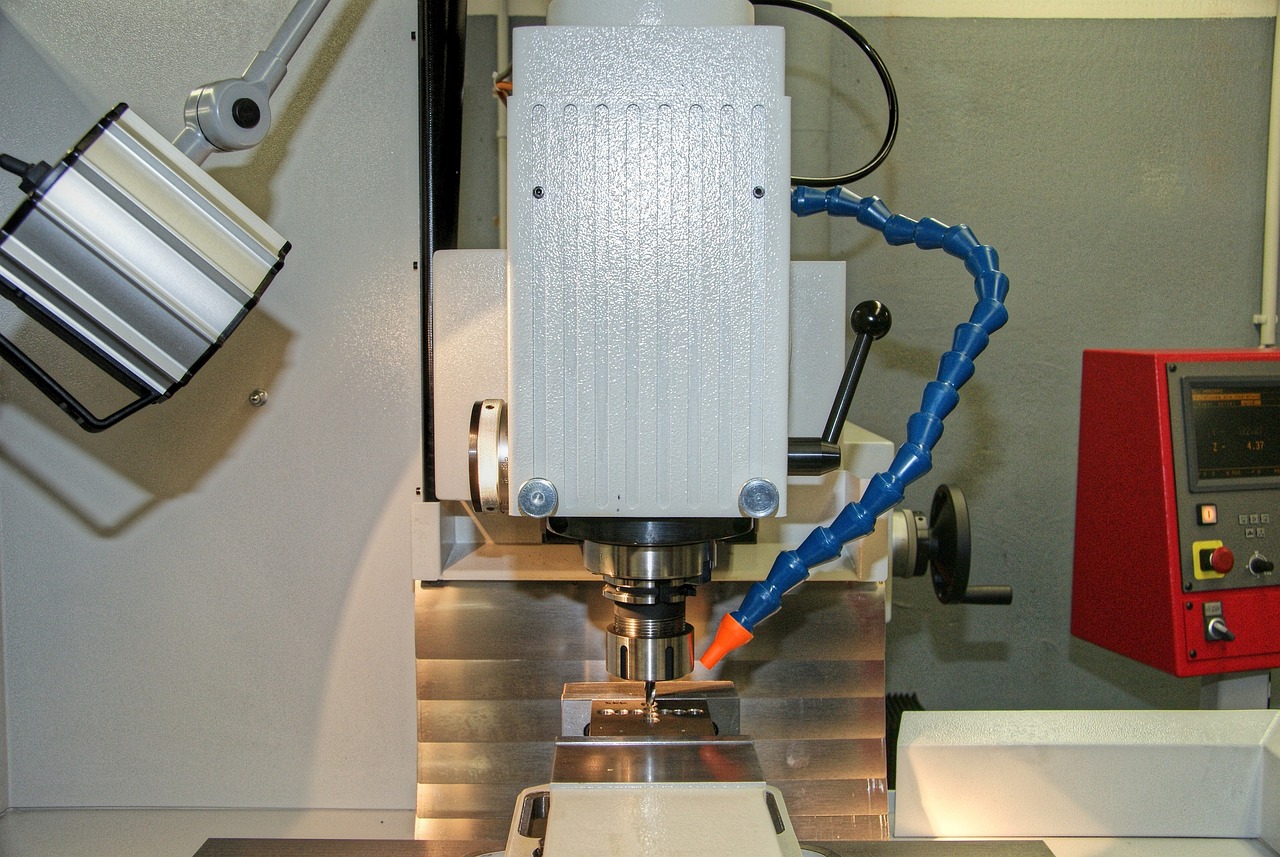

Production Tooling Design Advancements with Custom Jigs & Fixtures

Advancements in production tooling design have significantly improved manufacturing efficiency by integrating custom jigs and fixtures. These specialised tools are meticulously designed to meet the specific requirements of each production process, ensuring consistency and precision. Custom jigs and fixtures optimise production lines, reducing errors and improving overall quality while maintaining high standards.

The latest developments in production tooling solutions focus on enhancing both flexibility and productivity. Custom tooling solutions eliminate the need for frequent adjustments, allowing for smooth and continuous production. Tailored to specific needs, these advancements not only maximise resource use but also extend the lifespan of machinery, offering long-term benefits to manufacturers.

Streamlining Workflows with Production Tooling Design and Custom Solutions

Simplifying production processes is a major objective for every company trying to increase productivity. This is made possible by production tooling design, which enables manufacturers to reduce the number of stages needed in the production process. Implementing custom fixtures and jigs makes the workflow simpler, lowers the possibility of mistakes, and increases productivity all around.

Every component is properly positioned and held in place during the manufacturing process thanks to the use of sophisticated custom tooling engineering. Custom solutions remove the need for recalibration or manual changes during production, which frequently causes operations to lag. Key strategies for streamlining workflows include the following:

• Reduced Setup Time: Custom jigs minimise setup time by ensuring precise and rapid positioning of components.

• Increased Production Speed: Streamlined workflows are achieved through the elimination of frequent adjustments, allowing for faster production cycles.

• Improved Component Accuracy: Each part is crafted to exact specifications, resulting in fewer defects and less rework.

• Lower Manufacturing Costs: Reduced waste and fewer errors lead to direct cost savings throughout the production process.

• Minimised Downtime: Custom fixtures ensure machines run smoothly, significantly reducing the need for production halts.

• Enhanced Flexibility: Custom tooling solutions can be easily adapted for various tasks, offering manufacturers greater versatility in production.

• Optimised Resource Use: Improved efficiency in production lines leads to a more effective use of materials and machinery, maximising overall productivity.

Effective industrial tooling development, combined with custom jigs and fixtures, significantly enhances manufacturing efficiency and precision. This integrated approach ensures smoother operations, better resource management, and superior quality.

Semtool Engineering, provides CNC machining and precision engineering solutions, specialising in custom jigs, fixtures, and automation systems that enhance manufacturing efficiency. Drive operational excellence with our custom tooling solutions, built to reduce waste and improve part consistency.