Discover how Sustainable Tooling Design using CNC Milling Services can minimise environmental impact and material waste. Learn from Semtool Engineering.

Manufacturers today are increasingly seeking ways to minimise their environmental impact. Sustainable tooling design, which incorporates eco-friendly practices throughout the manufacturing process, plays a crucial role in achieving this goal.

Here at Semtool Engineering, a leading provider of CNC milling services in Melbourne, we understand the importance of sustainable practices and are committed to helping our clients achieve their environmental goals.

The Importance of Sustainable Tooling Design

The manufacturing industry is a significant contributor to environmental degradation and waste generation. The production process involves the use of various materials, energy, and resources, which can have a substantial ecological footprint. Tooling design, in particular, has a significant impact on the environmental sustainability of a manufacturing process.

Traditional tooling design methods often result in excessive material waste, energy consumption, and environmental pollution. However, with the increasing awareness of environmental concerns, the need for sustainable tooling design has become more pressing.

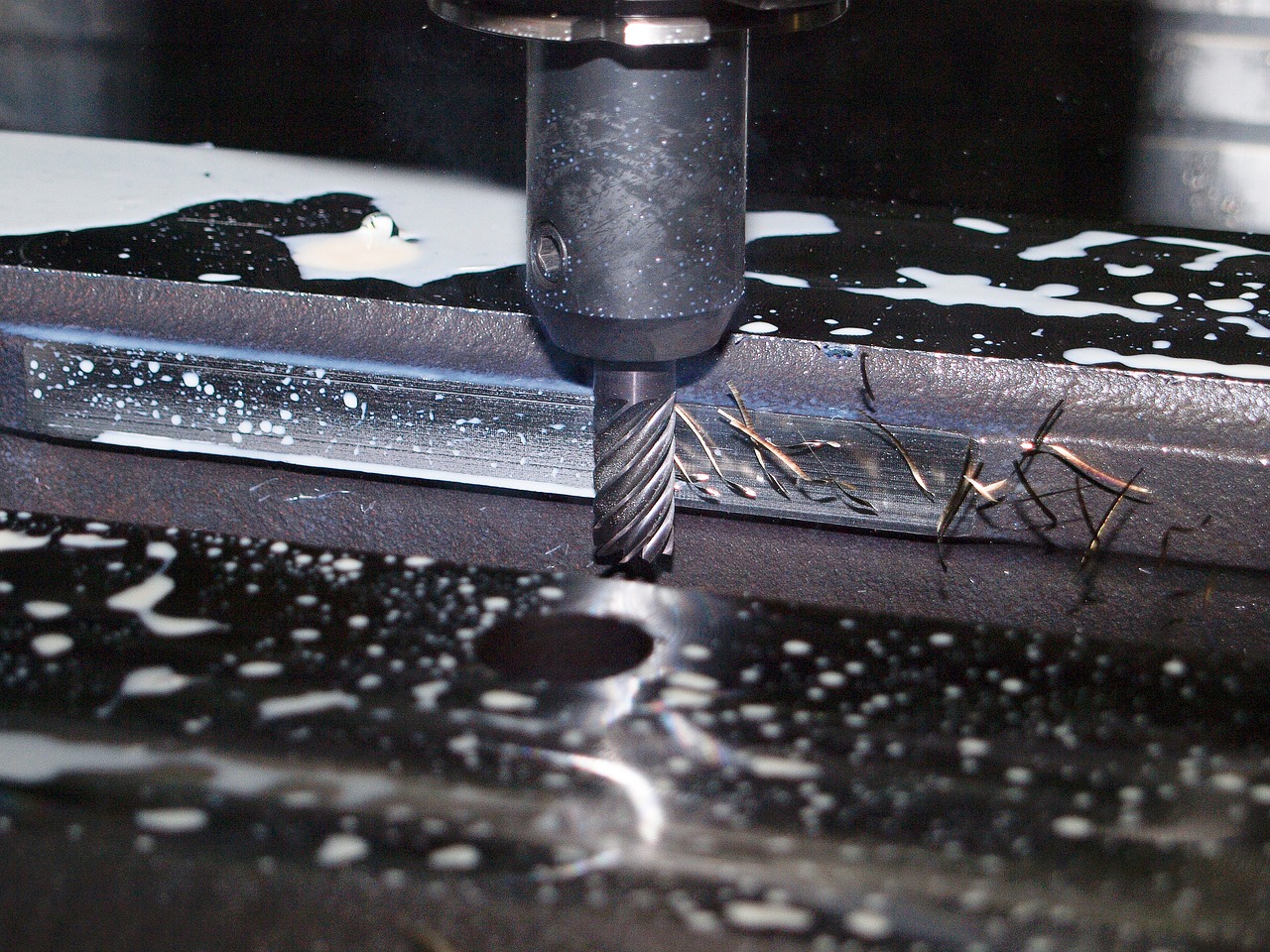

CNC Milling Services for Sustainable Tooling Design

CNC milling services are a critical component of sustainable tooling design. CNC machining offers several advantages that can help minimise environmental impact and material waste. Here are some key benefits:

• Precise Control: CNC machining provides precise control over the manufacturing process, allowing for the creation of complex geometries and shapes with minimal material waste.

• Efficient Material Utilisation: CNC milling services enable the efficient utilisation of materials, reducing the amount of waste generated during production.

• Reduced Energy Consumption: CNC machining is a more energy-efficient process compared to traditional machining methods, resulting in lower energy consumption and reduced carbon emissions.

• Customisation: CNC milling services allow for the creation of custom tools and components tailored to specific industry needs, reducing the need for generic, wasteful designs.

• Scalability: CNC machining can be scaled up or down depending on production requirements, making it an adaptable solution for various industries.

Implementing Sustainable Tooling Design

To implement sustainable tooling design, Semtool Engineering follows a comprehensive approach that includes:

Design for Manufacturability – Our design team focuses on creating tools and components that are optimised for manufacturing, reducing material waste and energy consumption.

Material Selection – We select materials that are environmentally friendly, recyclable, and have a lower carbon footprint.

Process Optimisation – Our CNC machining services are optimised to minimise energy consumption and reduce waste generation.

Recycling and Reuse – We encourage the recycling and reuse of materials wherever possible, reducing the need for new raw materials and minimising waste.

Minimise Environmental Impact and Material Waste – Semtool Engineering

By embracing sustainable tooling design principles and partnering with a forward-thinking CNC milling service provider like Semtool Engineering, you can significantly reduce your environmental impact and contribute to a greener future.

Our commitment to sustainable practices, combined with our expertise in CNC milling technology, allows us to create high-quality, durable tools that minimise material waste and energy consumption.

Contact Semtool Engineering today to discuss your specific tooling design needs and explore how our CNC milling services can help you achieve your environmental and manufacturing goals.